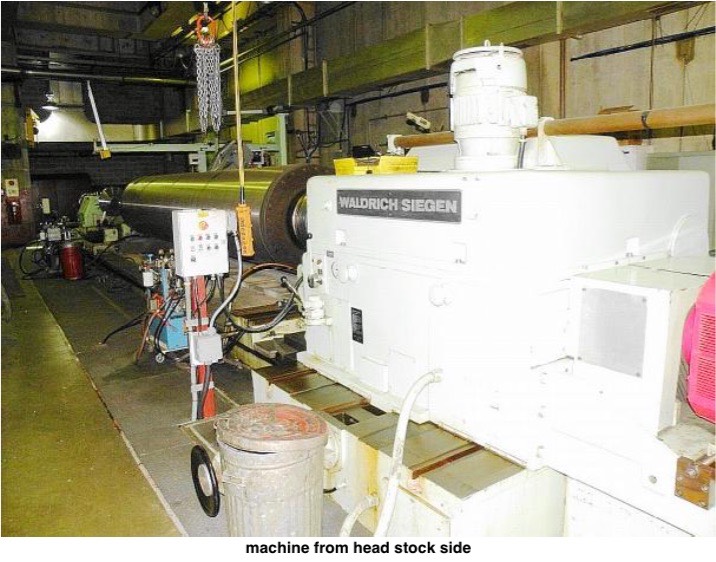

Roll grinder, CNC Waldrich Siegen Type: WST IV H 70 x 13.000

The asking price of this machine is below 25% of the new price

Year of manufacture: 1981

Upgraded Including new control and electrics: 2007

Cost of rebuild: $700,000

Condition: As New

Status: Dismantled by Waldrich professional staff and in secure storage

Complete running spares inventory: Available as required.

Technical Data

Working range

max. roll-∅: 2,000mm

min. roll-∅: 0mmm

max. length of roll: 13,000mm

max. weight of roll: 70 tons

Headstock with starter motor

- main motor: 73,55 kW

- speeds of main motor, infinitely variable: 450 - 1,800rpm

- revolutions at face plate 1. step: 5-50 rpm

- revolutions at face plate 2. step: 50-500 rpm

- traverse adjustment: 600mm

Grinding carriage

- grinding spindle speeds: 450 – 1.800rpm

- cutting speed: 45 m/s

- grinding spindle motor: 40kW

- travel distance, longitudinal: 12.600 mm

- feed, infinitely variable: 60 – 4,000 mm/min

- travel distance, traverse: 650 mm

- rapid adjustment: 400 mm/min

- continius infeed, abnormal: 0.00375 – 1.125mm/min

- final infeed: 0.0056 – 0.056 mm/stroke

- manual adjustment, rough fine:

0.1 0.025 mm/rev.

0.1 0.025 mm/rev.

Abrasive wheel

- dia. 800 mm

widths: 90 mm

widths: 90 mm- boring: 304.8 mm

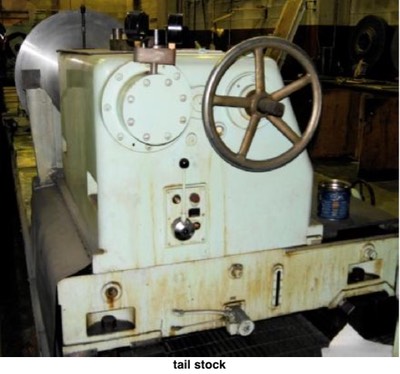

Tail stock

- adjustment of quill: 260mm

- adjustment way, traverse: 600 mm

- adjustment way, longitudinal 13,400mm

Main dimensions

- length of machine: 20,200mm

- width of machine: 4,800mm

- height of machine: 2,200mm

- weight of machine aprox.: 85,000kg

- Electric voltage: 575V 60Hz

Technology and Accessories

- • hydrostatic guide ways in z and x axis and grinding spindle

- • new electric cabinet in 2007

- • new CNC control ALLEN BRADLEY 1395 in 2007

- • complete new cable for the machine in 2007

- • two bed system, grinding and work piece side are separately

- • bed with grinding carriage, operators platform and CNC control unit

- • automatic grinding wheel DIA compensation (compensation of speed)

- • automatic reversing of z-axis when length (limit) of roll body will reached

- • telescopic way covers for z axis

- • 2 steady rest 200 – 500 mm

- • 2 hydrostatic steady rest 755/780/860/890 mm

- • 1 supporting steady, 2 quill design, 175 – 1.050 mm

- • work piece measuring device

- • belt grinding device

- • 15 abrasive wheel centres

The machine is already dismantled and stored in Vancouver Canada.

In 2007 was the machine completely remanufactured and equipped with

Scope of remanufacturing in 2007

- new CNC control HERKULES HCC, with WALDRICH SIEGEN GPC 2 software

- new electric cabinet

- new wiring inside the machine and between machine and cabinet

- cambering device is changed from a gear box to a ball bearing spindle with electric motor

- new motors for the head stock, z and x axis

- new measuring system for x and z axis

- new venta nip device

- new belt grinding device

REFURBISHMENT

The remanufacturing job was done by company KPM USA, a daughter company from HERKULES/WALDRICH SIEGEN. The price of the complete remanufacturing was US$ 700,000.

After remanufacturing the machine worked for only for 500 hours, then the paper mill (four paper machines) was closed. The machine is absolutely in as new condition and has still the accuracy of a new machine. In z and x axis, the guide ways are hydrostatic, also the grinding spindle bearing.

The new price from WALDRICH SIEGEN of a large machine like this is 4,7 Mio Euro.

It is a unique possibility to get a top machine for less than 25 % of the new price.

If you have any questions, please do not hesitate to contact us.