SM0713: 2,500mm PAPER MACHINE 75 Tpd; 100-200 gsm;Kraft, wrapping paper, corrugating medium using only recycled fiber

Technical report describing the plant

Geographical location.

Europe

Description of the facilities.

The current plant began its activity with the production of rice paper. After a long process of restructuring to meet the new requirements, the company now produces wrapping paper in rolls for corrugating using only recycled fiber.

The restructuring process has focused on providing the most dough preparation stage of purging in order to obtain a much cleaner and a greater recovery of fibers, up to touch every point across machine.

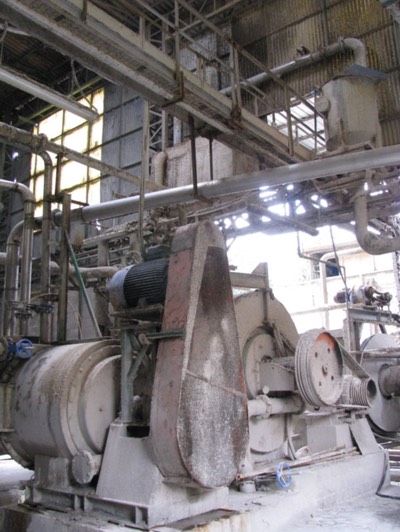

Noting the different machines installed, the cycle is broken down in the stock preparation, machine, central heating, air purification, services.

Preparation of Stock

As previously mentioned, the stock preparation involves several stages of purging in order to get a cleaner finished product and always responsive to customer needs. The mill therefore installed the machinery below listed:

- Pulper Toschi low density of 30 m3, equipped with control panels, tape power, etc..

- Trommel washing and recovering waste fiber Inox BF pulper complete with baling press and conveying the same in the container automatically collected.

- Turbo Separator OMMA with a production capacity of 120 tons / day.

- Separplast S.T.M S.r.l. S Mod V 4.

- Recovery of fiber (type Krofta) for water treatment process.

All machines are supplied with the relevant lines and service connections made entirely of stainless steel, fuel pumps and service, electrical, plumbing and Pneumatics made in accordance with current regulations.

Production Line

The machine continues arising from the restructuring process has been assembled with the machines listed below:

- Headbox slice 2,700 mm of useful width.

- Table length of 28.20 m. X 2.83 m, made up of foild, low suction vacuum boxes, high vacuum suction boxes,

- Corsini press section made built in 2009

- Plant consists of 4 x vacuum pumps (Azmec Spa)

- Drying section consists of 33 drying cylinders (Carcano and Maule) combined from 4 to 3.5 bar batteries with cylinders. Steam produced by the plant in 2009 with Novimpianti dryer hood and air-conditioning machine room.

- Winding Toschi light cutting of 2,500 mm and cutting pneumatic Cotta SpA

- machine control via new installation by the company Siei Systems Srl

On the production line is installed an automatic control of electronic weight and moisture switchboard and control panels installed on hardware and software in 2009 by the STC.

The whole machine is still accompanied by relevant Line and service connection made entirely of stainless steel, fuel pumps and service, installation and electrical room, hydraulic and pneumatic systems made in accordance with current regulations.

Thermal power plant.

The current plant is equipped with a cabin built second gas intermante current regulations by the company Tormene Technologyes Spa for the arrival and distribution of methane gas in thermal power plant in which they are installed No 02 boilers

Therma Spa from 8,000 kg / h of steam. At the same service for the treatment of No water supply are 01 reverse osmosis and n. 01 plant demineralization.

Effluent treatment plant.

The plant has a treatment plant for water treatment process, complying with building regulations in force of approximately 200 m2 consists of a first tank of chemical treatment of primary physical locations-flotation, followed by a stage activated sludge produced by aerobic oxidation with two tanks placed in

series, followed by a final settling tank for settling and recovery biological sludge, which is recycled in a paper machine, or thickened with a special press sedimentation sludge.

Concluding Remarks

The original production plant for the manufacture of straw paper was constructed by the company Maule F. & G. In 1994 the plant underwent a major restructuring in large part reusing the adapting existing machinery to the new machine configuration and purchasing to replace parts on both new and second hand market.

Description Unit of measure Value Tolerance

Working width mm 2,500+ 3% profit

Weight min. g/m2 100 + 3%

Weight max. g/m2 200 + 3%

Daily ProductionTons per day75dependant on product

Finished Roll outer dia max. mm1,400 + 3%

Finished Roll outer dia min. mm1,250 + 3%

Core diameter hole mm 100 + 3%