BOARD MACHINE, 2,330 mm,CELLI, CORE BOARD, KRAFT, BAGS, 15 TPD.

- General data

- Location: Europe

- Type of PM: Vat formers

- Manufacturer: G.CELLI

- Status: completely assembled

- Paper grades: cored board, kraft, bags

- Basis weight range: 50 - 200 gsm

- Production: 15 TPD

- Max. speed: 80 mpm

- Paper width at reel: 2330 mm

- Max. diameter of finished roll at reel section: 1500 mm

- Raw material: 100% selected waste

- Tension at mill: AC, 400 V - 50 Hz

- Installed power of 75 kW

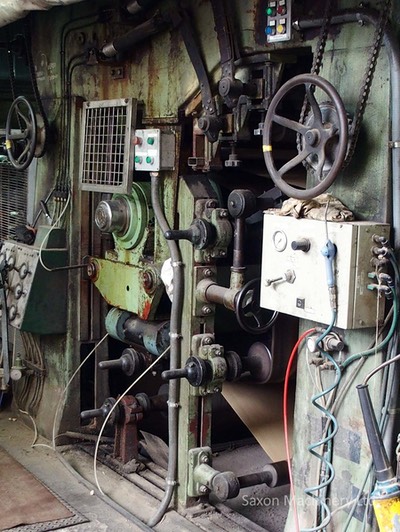

- Drive: mechanical transmission

2. Other information

- Plant & machinery in good mechanical conditions (frameworks in cast iron)

- Investment addressed to companies looking for small output and outstanding quality of final products (paper with high margin of profit)

- Visits welcomed prior to written consent of the Seller

- The plant & machinery was stopped in October 2014 due to critical market conditions and negative expectations

- The mill is in voluntary liquidation procedure

- SAXON MACHINERY Ltd. is the preferred company appointed for the sale of assets, the best conditions ever only and exclusively through SAXON

3. Parts for sale

- Stock preparation system (paragraph 4)

- Paper machinery and related auxiliary systems (paragraph 5)

- Winder machine (paragraph 6)

- Rewinder machine (paragraph 7)

- Steam generation plant (paragraph 8)

- Effluent treatment equipment (paragraph 9)

- Spare parts available at mill (paragraph 10)

4. Description of stock preparation plant

- (1) Toschi medium consistency pulper (5% TSS) of perforated plate and extraction chamber, 8 cm of volume, maximum production of 16 TPD, V-belt transmission, installed power of 75 kW, discharging pump ROBUSCHI RK 80/SS, 11 kW

- (1) Dumping chest in stainless steel, capacity of 35 cm, completed of agitator having installed power of 11 kW, discharging pump of 11 kW

- (1) High consistency cleaner for the removal of heavy contaminants, COMER 400 lpm, manual discharge of rejects

- (2) A. CELLI De-flaker D5 type, installed power of 55 kW each

- (1) AGA single disk refiner 17”, installed power of 110 kW

- (1) AIRAGHI conical refiner, installed power of 22 kW

- (1) vibrating screen , 0.8 m^2, perforated plate in stainless steel with 1.2 mm diameter holes, installed power of 4 kW

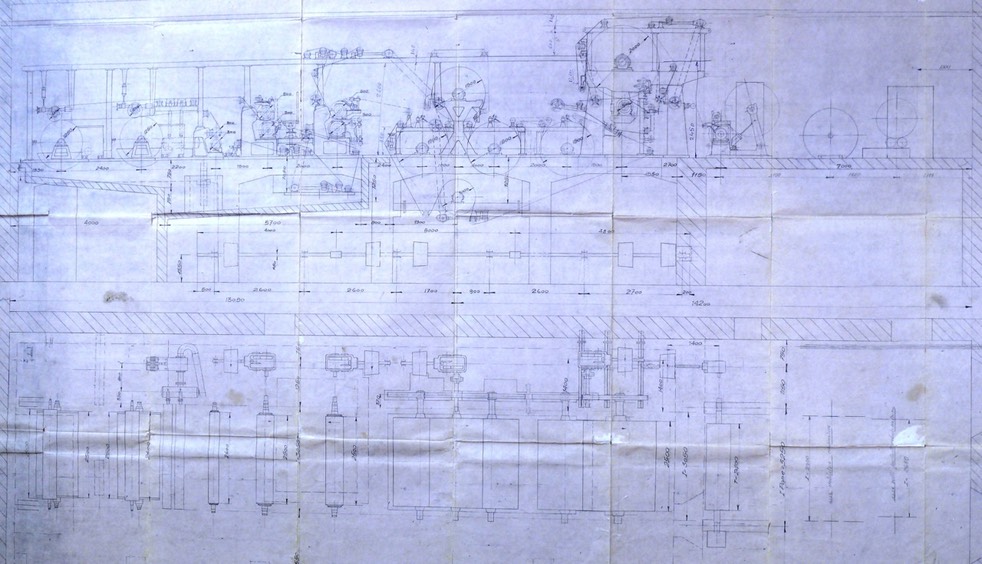

5. Description of the paper machine

- Wet end framework in painted cast iron

- (2) vat formers in cast iron, 1250 mm diameter, completed of open head boxes having distributor rolls

- (2) top rolls, 400 X 2600 mm, rubber covered

- (3) suction boxes

- (2) bottom felted presses having two 500 mm diameter rolls in cast iron, bottom roll rubber covered and grooved

- (2) presses having rolls 300 mm diameter for felts dewatering

- (2) felt runs completed of guide and stretcher devices

- Completed of tail cutter

- Dryer section in painted cast iron

- (3) dryers in cast iron, 1500 mm diameter, 2500 mm of face, designed steam pressure of 3 bar

- (1) dryer for felt drying, 100 mm diameter, cast iron, designed steam pressure of 3 bar

- (1) Mono glazed cylinder of 2000 mm diameter, 2500 mm of face, designed steam pressure of 3 bar

- (1) press roll 500 mm diameter

- (2) oscillating blades

- (3) felt runs completed of guide and stretcher devices

- Complete of COMET open hood and thermal system

- Reel framework in painted cast iron

- Drum reel of 650 mm diameter, 2400 mm of face

- Completed of primary arms and secondary arms (the latter operated by hydraulic cylinders)

- (1) Hydraulic unit

- (1) Cleaning blade

- (3) reel spools

- T.G.S QCS system

- Auxiliary systems: vacuum plant, compressed air (2 compressors for a total capacity of around 6 cm/min @ 10 bar pressure, installed power of 18.5 + 22 kW)

6. Description of winder

- Two drum type, (2) drums having 260 mm diameter and 2300 mm of face, driven

- Designed and manufacture by G.CELLI

- (1) unwind section hosting parent roll of 1550 mm diameter maximum

- Max. speed of 220 mom

- Max. diameter of finished roll: 1000 mm

- Max paper width of finished roll: 2300 mm

- (9) knives, MARIO COTTA, on counter roll

- Diameter of core board: 76 mm

- Installed power of 30 kW

- Completed of spreader roll before cutting section

- Unwind mechanical brake

- Completed of hydraulic operated rider roll

- (1) hydraulic unit and control panel

- Complete of electric cabinet

7. Description of rewinder

- (1) unwind section hosting parent roll of 1000 mm diameter maximum

- Max. diameter of finished roll: 1000 mm

- Max paper width of inlet roll: 1200 mm

- (13) knives, 120 mm diameter, on counter roll, installed power of 1.1. kW

- Diameter of core board: 76 mm

- Installed power of 1.1 - 6.7 kW

- Completed of spreader roll before cutting section

- Unwind pneumatic brake

- Driven roll and counter roll slitter

- (2) reeling shaft (top and bottom)

- Completed of control panel and electric cabinet

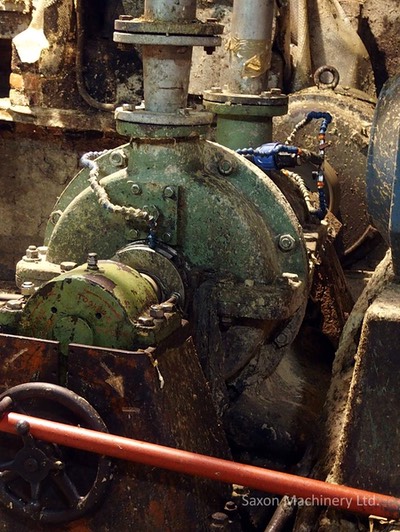

8. Description of steam plant

- Designed and manufactured by BONO Energy

- Fuel: natural gas

- Steam pressure of 12 bar

- Production of steam: 2000 kg/h

9. Description of effluent treatment

- Designed and manufactured by KROFTA

- Working principle: floatation

- Feeding pump having installed power of 22 kW

- Tank in stainless steel material, volume of 35 cm

10. Spare parts

Available at mill:

- (1) set of disk for de-flakers

- (1) vat former (without head box)

- (1) bottom press in cast iron, rubber covered, 500 mm diameter

- (1) ELLI right angle shaft reducer

- (1) felt for wet section (2.65 x 26 m)

- (1) felt for bottom press

- (1) glazing felt for Mono glazed cylinder

- (1) marking felt for MG cylinder

- (2) distributor rolls (head box)

- (1) ROBUSCHI pump, 600 m^3/h

11. Commercial conditions & services

The plant & machinery, including all parts mentioned in paragraph 3 (Parts for sale), is sold with the clause “as is where is”.

Dismantling and other additional services are not included in the scope of supply and selling price. Payment to be agreed with the Seller directly.

The selling price is available upon request, prior to registration of customer and signature of non disclosure agreement.

Total project finance may be available for qualifying companies and subject to specifc criteria. For further information, please contact us.

Complete package available upon request (purchase of assets, dismantling service, shipment, civil engineering, process engineering, project management, delivery of new parts, installation, start-up, training and trouble shooting services).