Sheet Cutter (synchro) , high - rotation small-size Hobema, Twin un-wind, A4/A3

In a sturdy , modern design for safe, continuous operation , designed according to our proven modular system that allows later additions and extensions , set up for the processing of documents up to 200g/m2

Working width: 450 mm

Cutting lengths: A4: 210 mm x 297 mm

Cutting length tolerance : + / - 0.2 mm

Max knife load : 400 g/m2

Power:up to 700 cut / min

The benefits are achieved in practice by the technical design of the machine , the next for processing material types and - influenced qualities as well as the quality of the mother roles

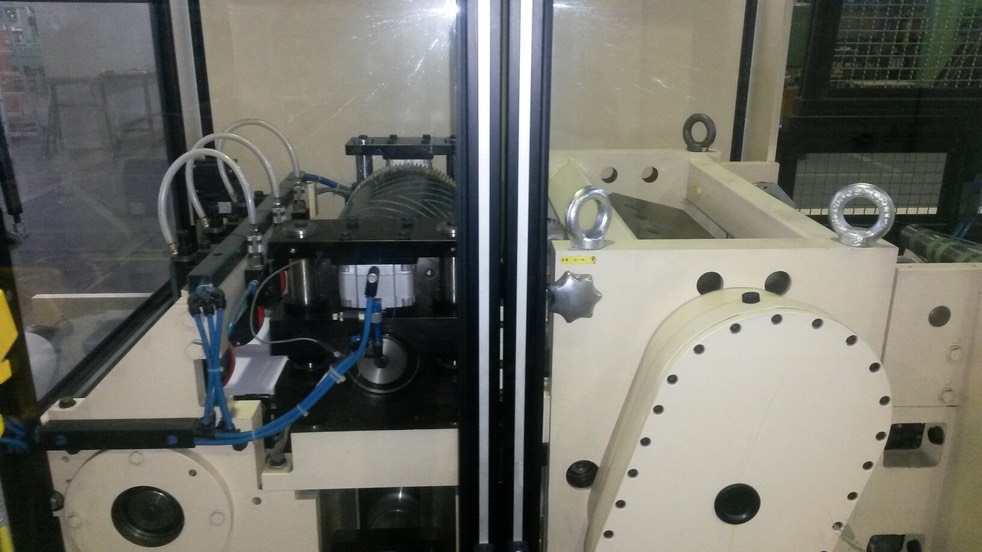

Drives: Maintenance-free individual servo- drive technology

Electrical design:

PLC: Siemens , S 7-400

Drives : Siemens Master Drive

Supply 3 AC 400 V, 50 /60 Hz mains voltage 400 V AC

Control voltage:

PLC components for DC 24 V

for safety circuits DC 24 V

Scope of delivery

For twin Unwind stations, working width 450 mm heavy steel construction with 2 cantilevered pneum. Shafts of Ø 76mm, suitable for quick roll changes , manual axial adjustment of + / - 15 mm , pneum . Disc brakes, two automatic train control systems via diameter , scanning by ultrasound sensor , max. Roll outside diameter of 1200 mm.

Plan - manually adjustable to reduce the curl of the web , flanged to the cross cutter

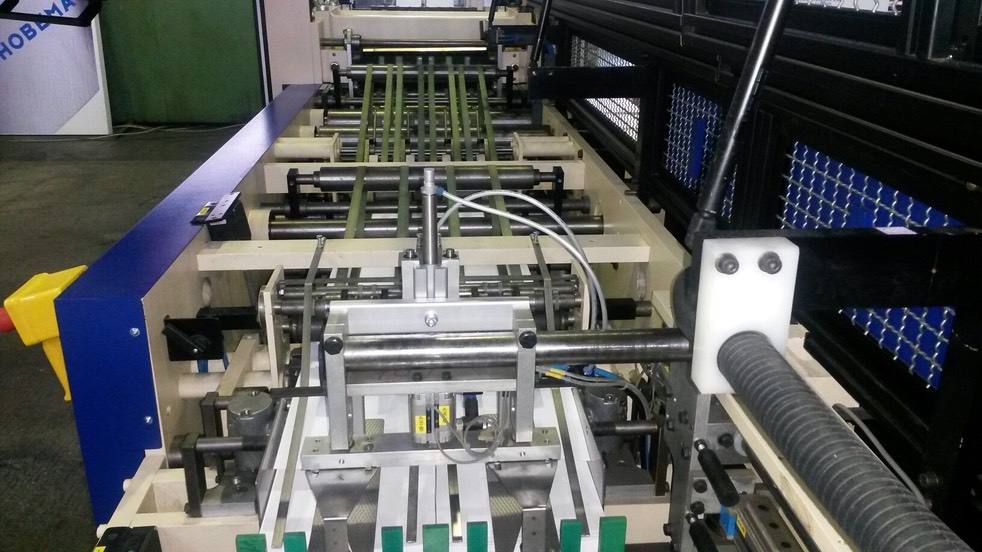

Slitter - With 3 pairs of circular cutting blades and the center section on both sides trim , the upper slitter blade is pneumatically thrown on and off , the lower slitter shaft is driven .

Edge Trim - with 2 intake , which open into a common suction pipe ; using an injector , the edge strip continuously, eg a site to alternate collecting container supplied . A delivery line of about 10m length is included.

Pair of feed rollers - large dimensions , consisting of a specially - oberflächenbehandel in lower steel roller with an outer diameter of 470mm and an upper rubber vulcanized Rhombenwalze with an electric conductive rubber pads, on and shut off the upper feed roll pneumatically. Drive the feed rollers via servo motor.

Rotating brush roller - disposed immediately before the inlet of the superposed webs in the cross- cutting station , the drive is effected by the cross- cutting station

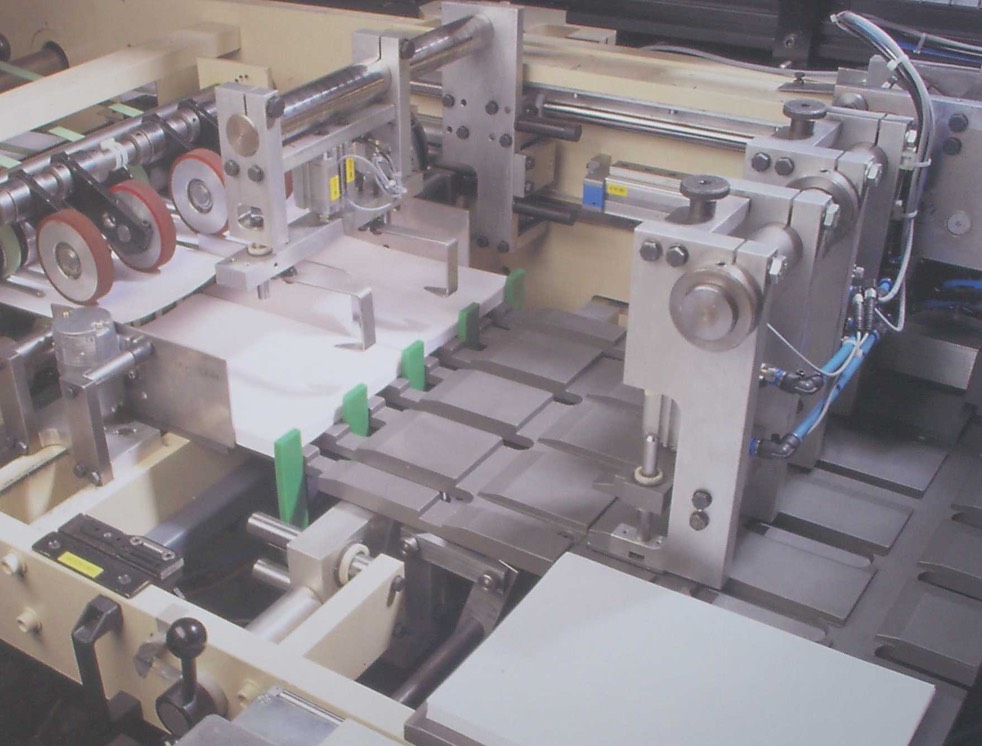

Transversely cutting station - equipped with:-

2 rotating cutter shafts , both equipped with 2 cross- cutting knives, rotary shear cut system

The drive of this station is via a servo motor.

Overlapping station - Speed on electronic continuously variable transmission , and it optimally tune the deposition speed on the material to be processed is the task of this station. With an overhead camshaft for absolutely safe dandruff

Automatic separating and transfer station - of producing stacks ( giant) with a predetermined number of sheets ( counted quantity ), standard number of sheets 250-500 sheets at 80 g/m2 paper , package height 25mm - 50mm . Transverse transport at a speed of an adapted conveyor for packaging machine

Section counter - with digital display

Fully digital AC drive system - with asynchronous and synchronous motors , protection class IP54 to IP65 inverter with three-phase supply , including Class A, Gr filters, chokes and radio interference suppression. 1, with frequency filters that prevent any faults affect other machines

Cabinet - completely wired , including cabinet cooling

Control panel - with all necessary operating and display elements

Guards - side , which prevents anyone accesses during the production run of the investment in the machine