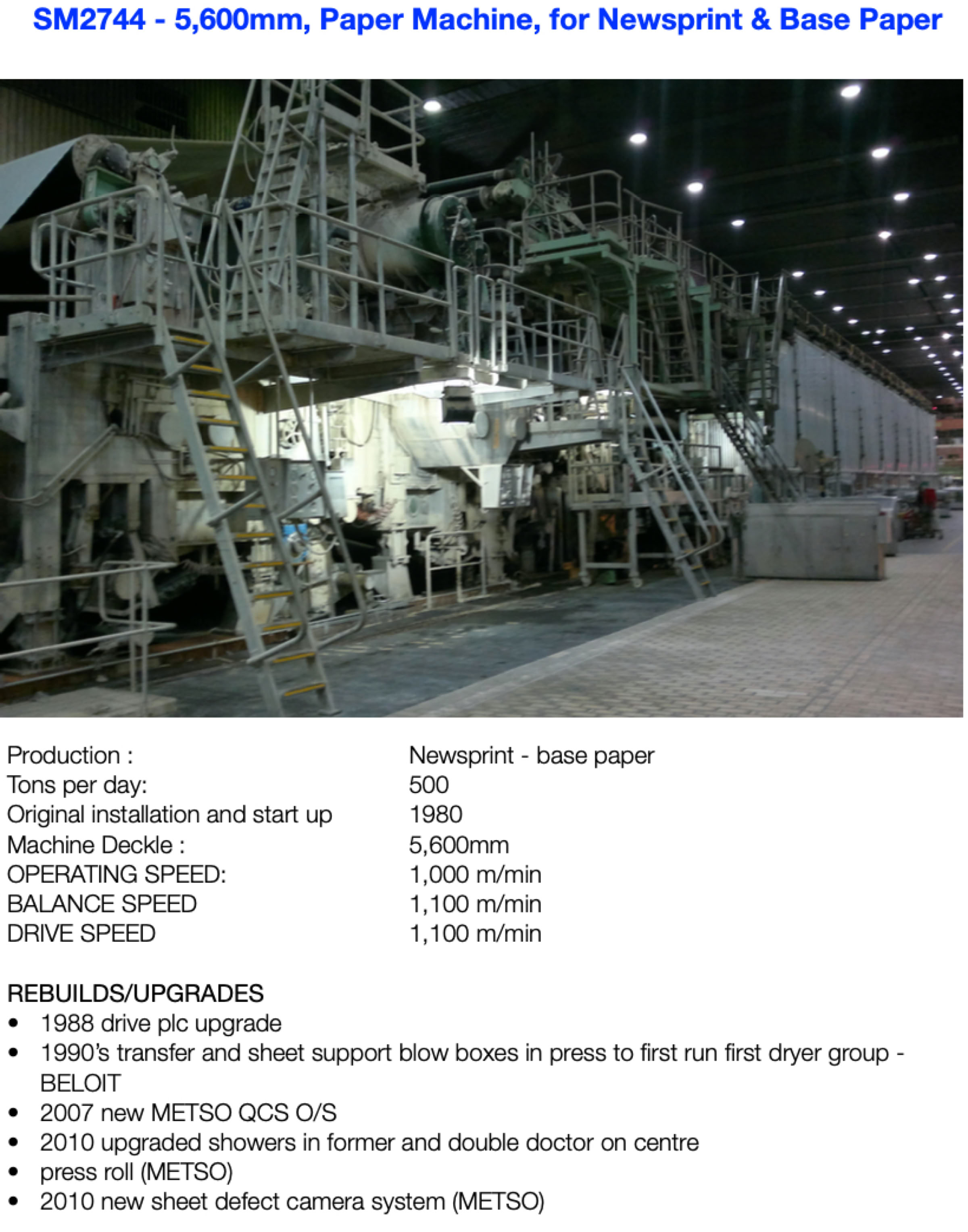

“NO NONSENSE MACHINES AT NO NONSENSE PRICES”

EXCLUSIVE AGENCY

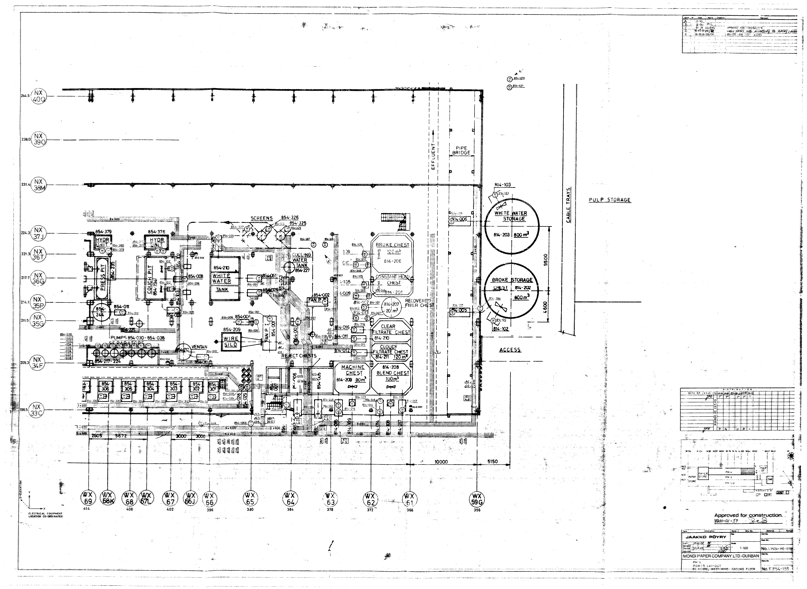

HEAD BOX:

• BELOIT ‘Converflo’ – with vanes Lamellas

FORMER

• Twin wire vertical gap former – BELOIT BELL-BAE 2

• Low vac and high vac ceramic boxes on both wires

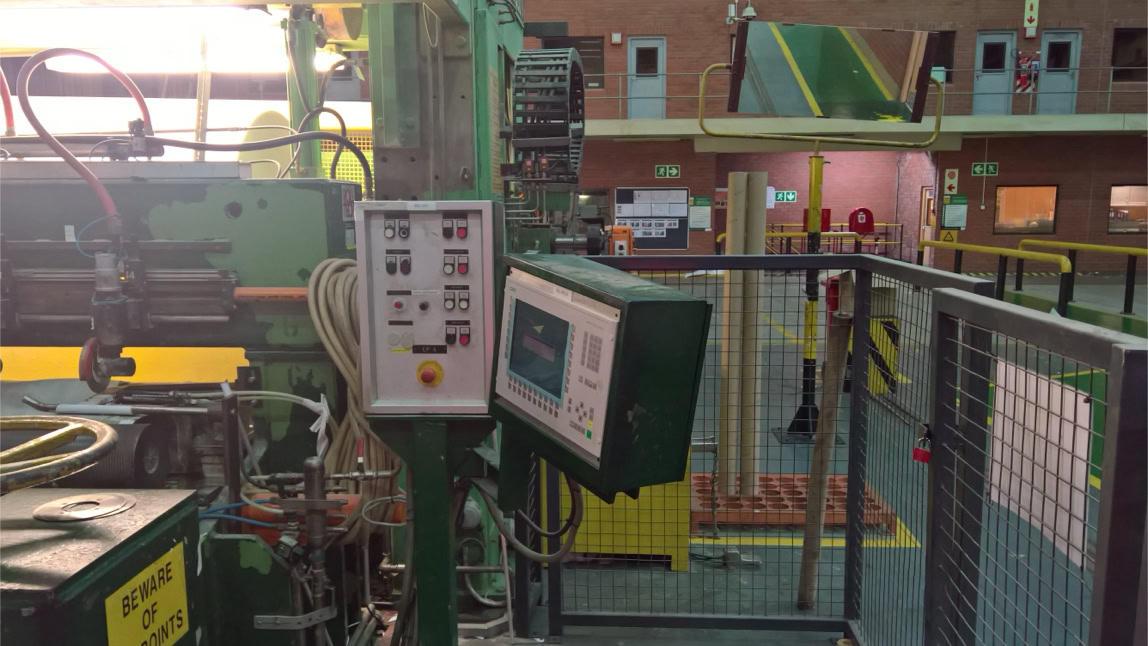

PRESS

• Standard configuration BELOIT Tri-Nip with standard suction pick-up

• 1st Press nip with basement felt = 70 kN/m

• 2nd Press nip with suction roll = 90 kN/m

• 3rd Press nip with grooved cc roll = 110 kN/m - Centre roll > top rock and ceramic covers

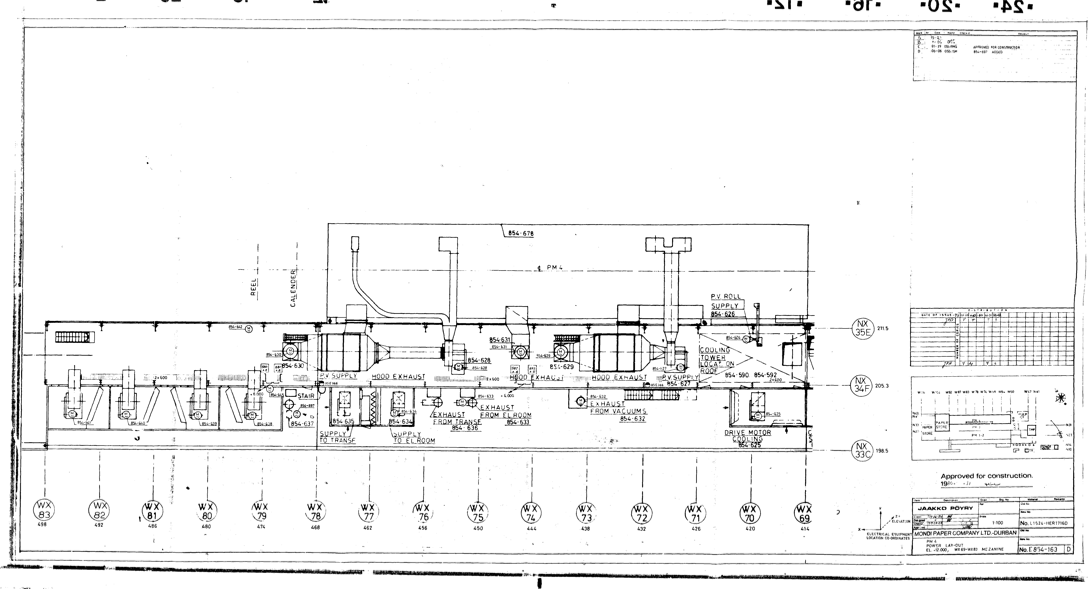

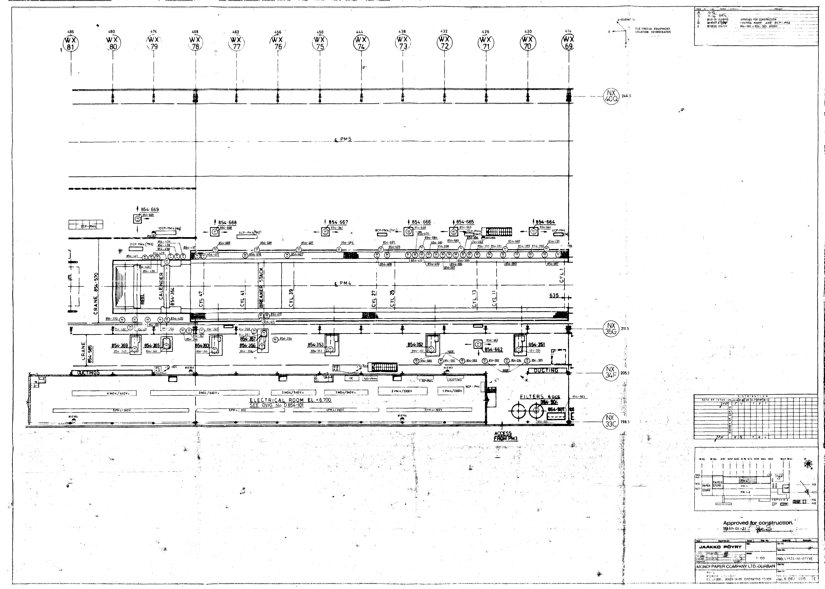

DRYER PART

FLÄKT

SLALOM (Uno-run) Group 1 -Conventional double run (felted) =Groups 2,3,4

Breaker stack between GRPS 3 + 4 removed c.2007

Conventional cascade steam& condensate system

Conventional hood exhaust / heat recovery

Conventional pocket ventilation system

Rope threading

Pressure rating 5 barg max

42 cylinders (cans)1500 mm

4 steam groups

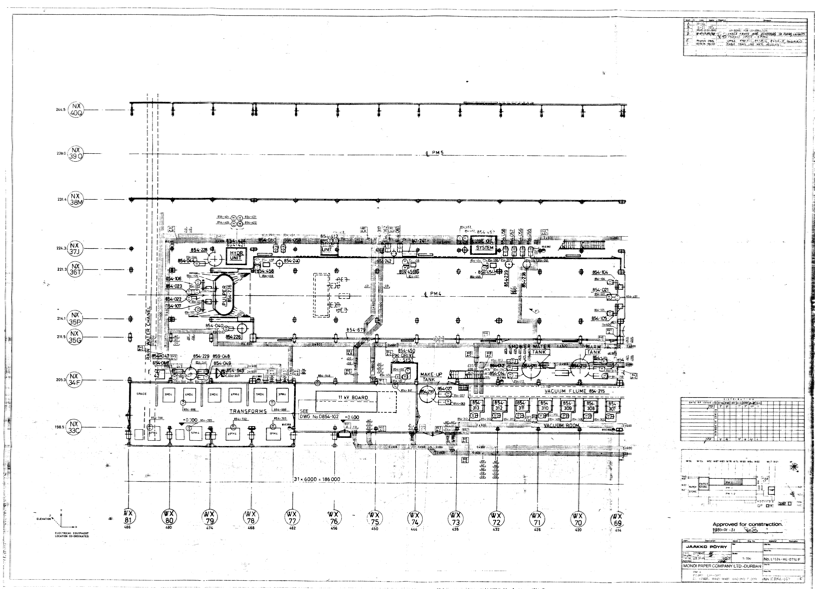

CALANDER

BELOIT 6 roll – 5 nip gravity loaded stack

BELOIT CC King roll

Queen roll – Counter pressure loading

Parallel rolls – 4 chilled iron

Air actuated nip relieving (edge-loads)

MACHINE PULPERS

Former / Press – non removable concrete chest

Dryer / Calander – non removable concrete chest

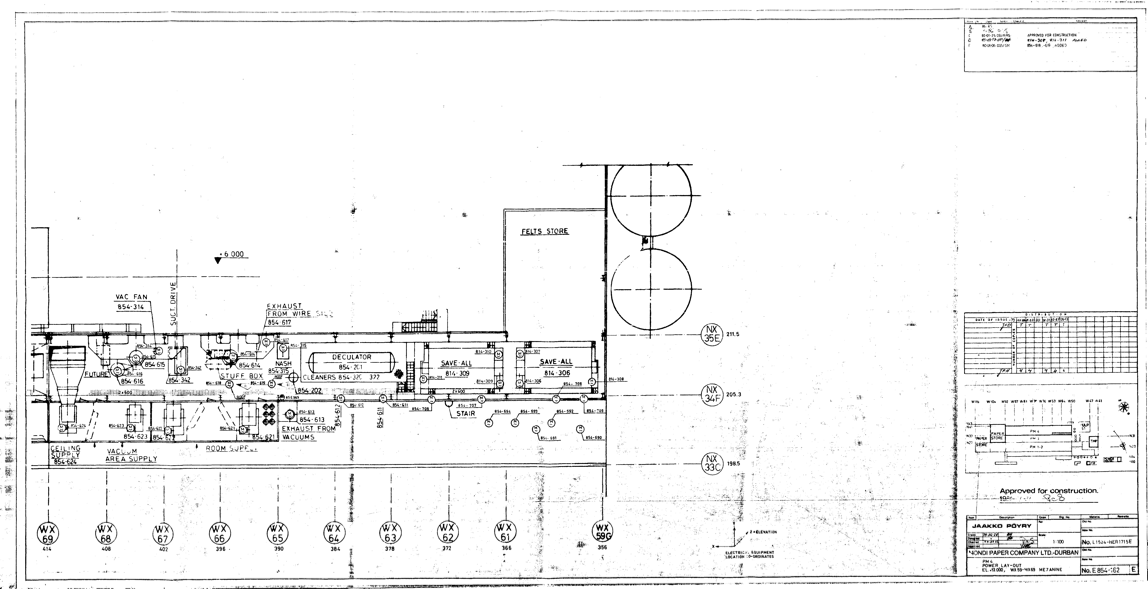

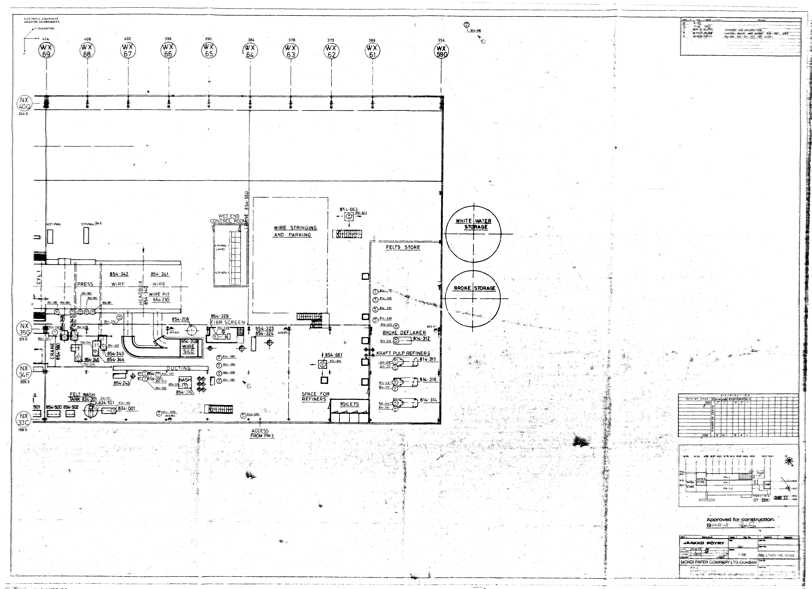

STOCK PREP

BELOIT softwood DD refiners series 4000 (upgraded 2008)42”plates

BLACK CLAWSON Softwood Hydra Pulper

APPROACH FLOW

CLARK and VICARIO deculator

BIRD machine (Head box) primary screens (x3)

Secondary and tertiary screens.

VACUUM PUMPS

Machine installed NASH Water-Ring Pumps series 4000 and 6000

ROLLS

S/Couch, pick-up and press suction all BELOIT

Press S/roll polyurethane cover blind drilled, drilled and grooved

FORMING AND PRESS SECTION

DRIER SECTION

MACHINE CALANDER