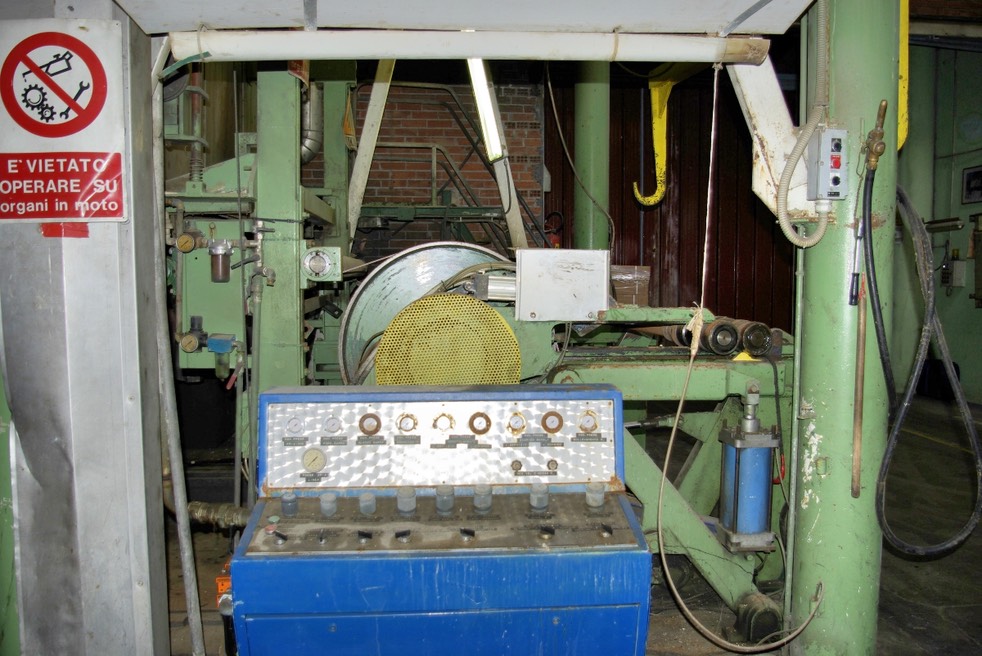

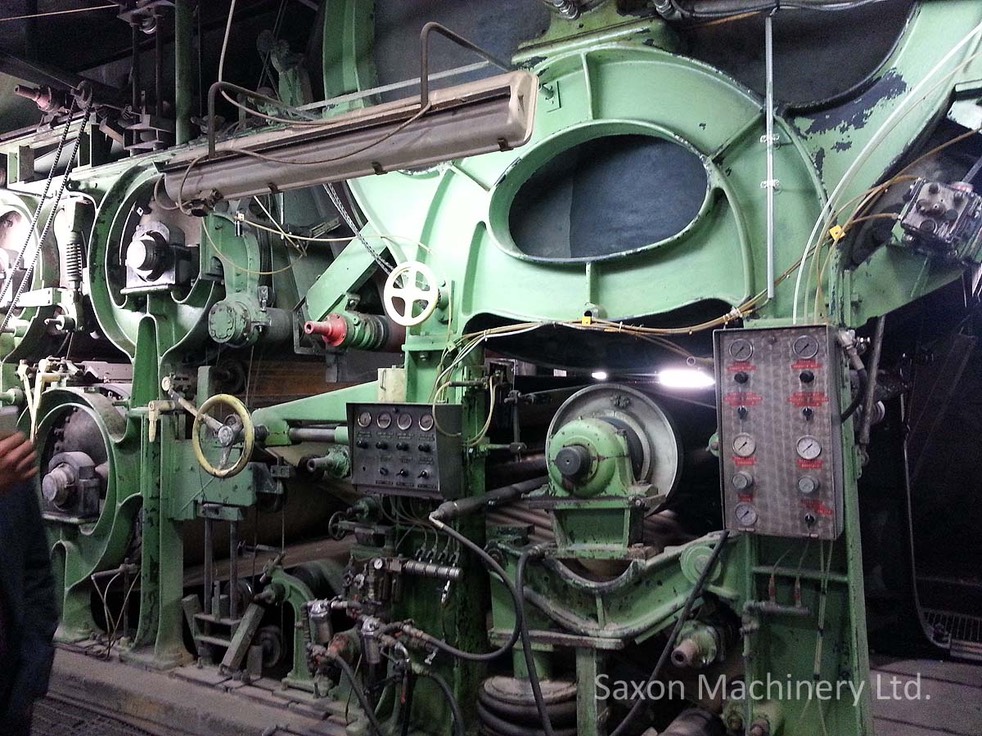

PAPER MACHINE, 1,700mm, KRAFT, BAGS, MG, SPECIALTY, 50-60 TPD

- NB. The current owner is offering an optional contract to the buyer of this machine to purchase all or part of the future production of the machine after relocation. This could be for a determined timeframe (from 2 years on) and at a fixed price.

- General data

- Location: Europe

- Type of PM: Fourdrinier

- Status: completely assembled

- Paper grades: kraft, bags, envelopes, MG, specialty papers (textile and furniture industry mainly)

- Basis weight range: 45 - 300 gsm

- Production: 50-60 TPD (maximum)

- Max. speed: 300 mpm

- Paper width at reel: 1700 mm

- Raw material: 100% selected waste

- Tension at mill: AC, 400 V - 50 Hz

- Available power at mill of 2 MW (two transformers of 1 MW each)

- Total absorbed power of 1.7 MW

- Drive: mechanical transmission

2. Other information

- Plant & machinery in good mechanical conditions, completed of main spare parts

- Investment addressed to companies looking for small output and outstanding quality of final products

- Visits welcomed prior to written consent of the Seller

- The plant & machinery was stopped in mid 2013 due to critical market conditions and negative expectations

- SAXON MACHINERY Ltd. is the preferred company appointed for the sale of assets, the best conditions ever only and exclusively through SAXON

- Low financial requirement

- The Seller offer themselves to become a client for the paper produced if prices are competitive, regardless of location (option to be agreed by separate contract)

3. Parts for sale

- Stock preparation system

- Paper machinery and related auxiliary systems

- Steam generation plant

- Effluent treatment equipment

- Spare parts available at mill

- Electrical energy distribution system

- (1) Fork lift

4. Description of stock preparation plant

- (1) Medium consistency pulper of 20 cm, working in batch mode, completed of extraction chamber and perforated plate, in carbon steel lined with stainless steel sheets

- (1) Medium consistency pulper of 12 cm, having the same characteristics of the above, used as spare in the event of maintenance

- Dumping pump having power of 30 kW, pump feeding the high consistency cleaner

- (1) MAULE HD cleaner 800 lpm for the removal of heavy impurities

- (1) MAULE Separplast GR.II type having stainless steed basket with 4 mm holes

- (1) Vibrating screen treating rejects from the Separplast

- (1) MAULE hot dispersion plant composed of (2) inclined screw thickeners, (1) dewatering press and (1) kneader (low speed, with steam injection, not pressurized), designed for 60 TPD

- (1) disk refiner 17”

- (1) disk refiner 18”

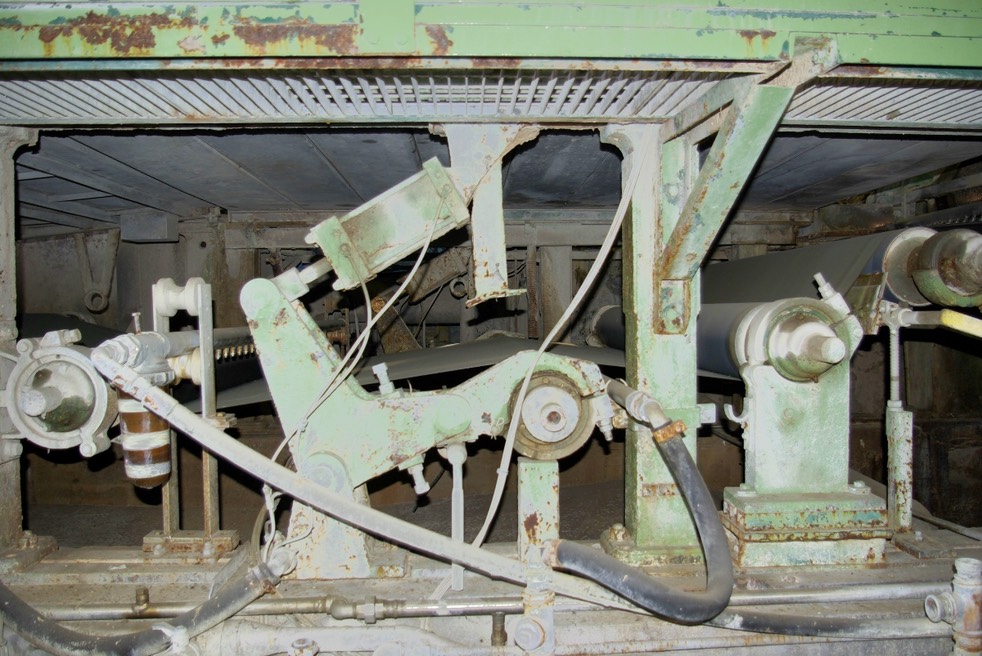

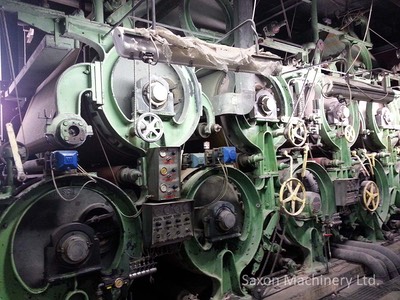

5. Description of the paper machine

- Approach flow system composed of constant level box, basis weight valve, tickler refiner 21”, silo, fan pump, three-stage low consistency cleaners, (1) LAMORT screen protecting the head box, (2) vibrating screens

- (1) Open head-box in stainless steel completed of manual slice lip control

- Fixed wire section having length of 11 m, wire of 2 X 23.4 m, composed of breast roll, foils, table rolls, vacuum boxes, suction couch roll, wire return rolls, ladder and walkways, framework in painted carbon steel

- Shaking device for wire section

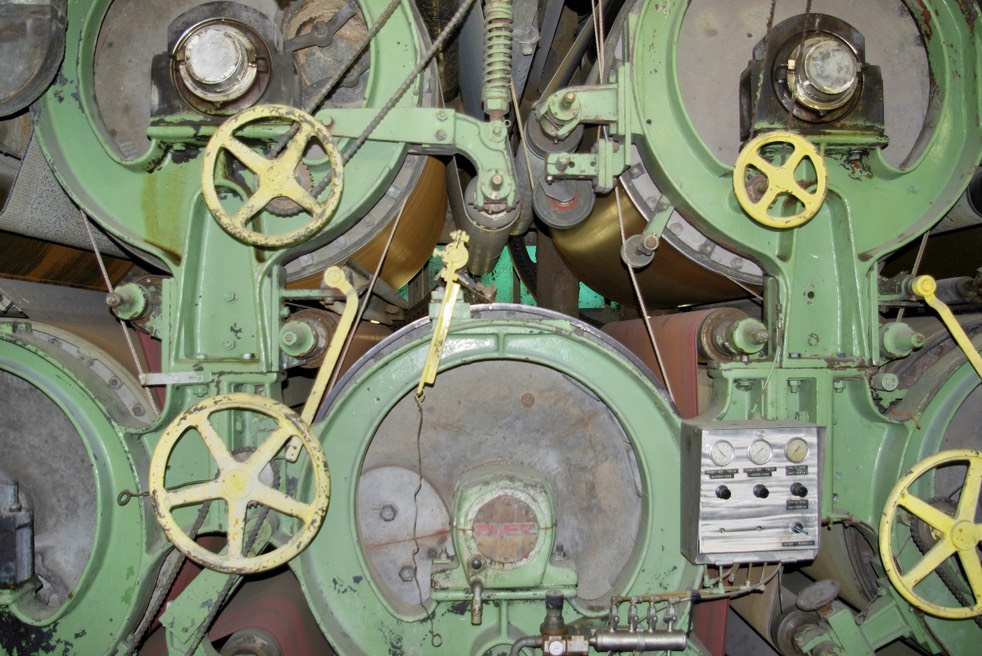

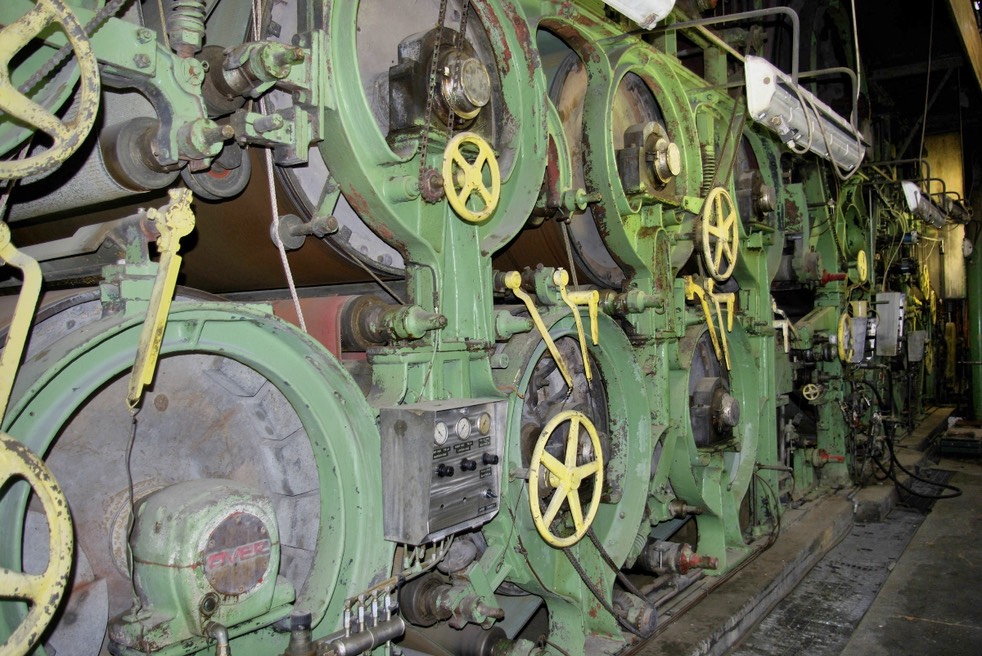

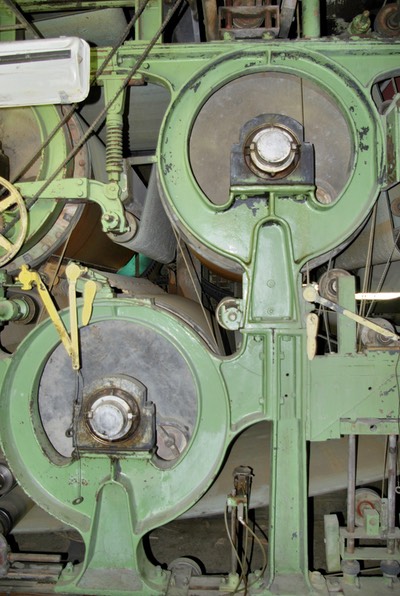

- 1st bottom felted press composed of (1) suction roll and (1) top granite roll

- 2nd bottom felted press composed of (1) grooved roll and (1) top roll covered in stonite

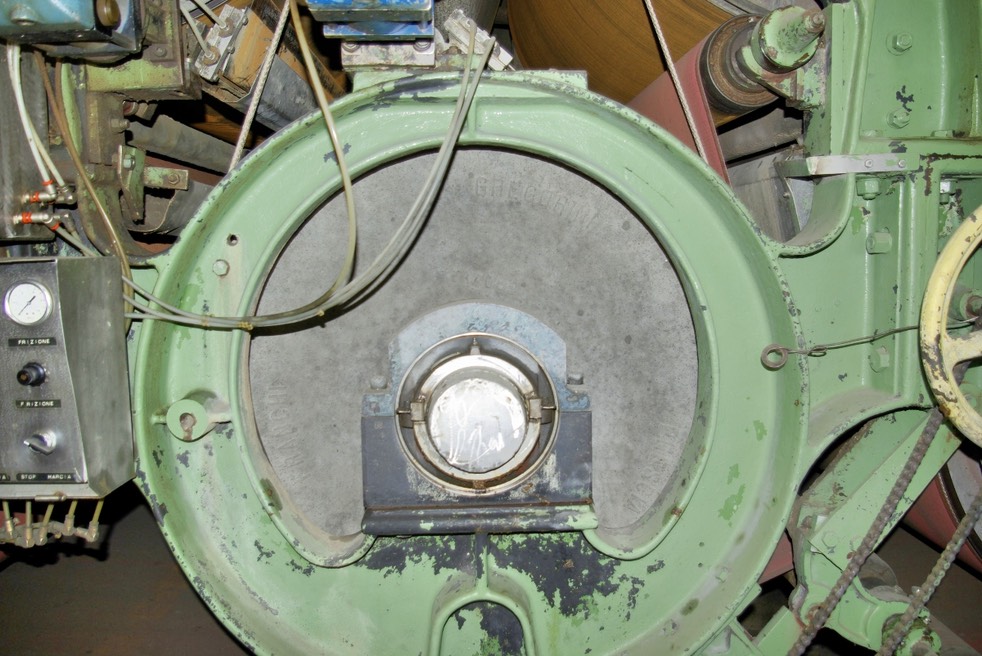

- (10) cast iron dryers, 1200 mm diameter, 1800 mm of face, maximum operating steam pressure of 2.5 bar

- (54) felt rolls

- (1) MG dryer, 3000 mm of diameter, 1800 mm of width, completed of press roll 500 mm diameter

- (3) cast iron dryers, 1200 mm diameter, 1800 mm of face, maximum operating steam pressure of 2.5 bar

- Pope reel, manual spool loading

- Auxiliary systems: vacuum plant (5 AZMEC pumps), LANG REGLER steam and condensate system, felt conditioning system, hydraulic units, steam generation plant made of (2) BONO boilers producing 3000 kg of stem per hour each at 15 bar pressure (oil fuel), water treatment system composed of (1) KOFTA Supercell 18 (vessel 8000 mm diameter in stainless steel), line of paper breaks (rarely in use, the efficiency of the PM is very high) composed of (1) MAULE inclined screw thickener and (1) drum thickener 3 having meters of length, distribution of electric energy at mill composed of (2) medium-low dry transformers (new), 1 MW each

- Completed of new electric cabinets

- Completed of a great variety of spare parts, the main of which are listed in the next paragraph

Main spare parts

Available at mill:

- (1) complete drive for pulper

- (1) vibrating screen

- main spares for MAULE inclined screw thickeners

- (2) AZMEC vacuum pumps

- (1) bronze shell for press couch roll

- (1) complete breast roll

- (1) wire roll and (9) felt rolls

- (1) suction press roll

- (2) press granite rolls

- (1) press grooved roll

- new wires and felts

- complete storage of finished products such as bearings, belts, screws and other consumables

- complete storage of electric motors and mechanical reducers

Commercial conditions & services

The plant & machinery, including all parts mentioned in paragraph 3 (Parts for sale), is sold with the clause “as is where is”.

Dismantling and other additional services are not included in the scope of supply and selling price. Payment to be agreed with the Seller directly.

The selling price is available upon request, prior to registration of customer and signature of non disclosure agreement.

Financing through SAXON MACHINERY Ltd. available for companies having the required characteristics. For further information, please contact us.

Complete package available upon request (purchase of assets, dismantling service, shipment, civil engineering, process engineering, project management, delivery of new parts, installation, start-up, training and trouble shooting services).

8. Documents

Pictures, front view drawing available upon request only