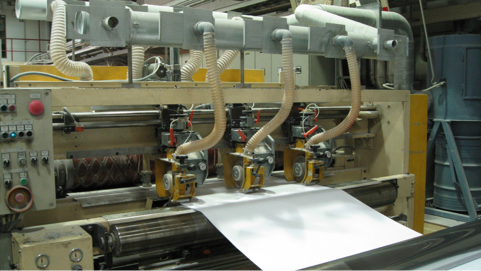

VALMET STRECKER SCR 1,600 SYNCHROFLY SHEET CUTTER (Automatic)

GENERAL DESCRIPTION

Valmet Strecker no 2022 is referred to as “fully automatic” due to the operation of the cutter when it happens from a control room. All parts in the cutter i.e. slitters, cross knives, two overlapping-, and two delivery sections will move to the correct positions automatically. The time for the change on the cutter is around 3 minutes.

The 4 reels unwind of type 2 x EA v 2/1500 are however not full automatic. It includes the reel preparation and auto loading but not splicing. It will be joined manually at the unwind stands. After setting the splice tapes on the preparation table, the reel conveyor moves 4 reels to unwind stands and lifts the reels between the core chucks. The core chucks penetrate the reel cores automatically when the reel conveyor has moved and lifted the reels between the stands.

The unwinds include lead rolls, tension and side control, de curling units and splice detector.

Auto splicing is not included. The joints will be finished manually at the unwind stands.

SPECIFICATION

- Mark and Model Automatic VALMET STRECKER SCR 1600 synchrofly high speed sheet cutter. Machine number 2022.

- Original Age 1988

- Full refurbishment 2016

- Width of the cutter Net 1,640 mm

- Cross cutting Synchro cross cutting for 40-600 gsm. Automatic size change by operation panel in the control room.

- Size change Sheet length change (automatic by operation panel); sheet length 400 -1,700 mm.

- Cutting accuracy Auto sheet length control +-0,3 mm.

- Speed Top Speed 350 m/min (constructional speed 400)

- Overlapping section Two vacuum overlapping sections

- Reject gate Reject gate operation connected to PLC

- Pallet change Auto non-stop pallet change in full running speed using two complete delivery sections (lay boys)

- Layboy Automated size change for 4 side joggers and back board (size change by operation panel). Sinking hydraulic pallet boards with automatic lamella conveyors for full pallets change and empty pallet feeder.

- Tab Inserters Tab Inserters included

- Slitters Full automatic size change (by operation panel) for three (3) slitters.

- Electric Complete electric system basing on PLC Siemens S5, 380 V 50 Hz.

- Unwind Unwinds for four (4) reels by 2 x EA v 2/1500. Reel preparation and loading unwind with hydraulic tables and conveyor. Complete lead rolls, tension and side control, de curling units for paper (dia 12 mm). Operated by PLC Siemens S7.

- Side trim system Edge trim devices with shredder, tubes and blower.

- Condition The line is in a good condition. Overhauling is made normally before the start of production. No special repairars are currently needed.

- Location Finland

Unwinds for four (4) reels by 2 x EA v 2/1500 including reel preparation and loading with hydraulic tables and conveyor. Complete lead rolls, tension & side control and de-curling units for paper (dia 12 mm). Operated by PLC Siemens S7.

After set splice tapes on the preparation table the reel conveyor moves the reels to unwind stands and lifts the reels between the core chucks, which penetrate into reel cores automatically.

Auto splicing is not included – webs joined manually at the unwind stands. Unwind section includes lead rolls, tension control, side control, de curling units and splice detector.

CUTTER HEAD AND AUTO SIZE CHANGE SLITTING UNITS WITH POCKET MOTORS AND DUST EXTRACTION SYSTEM

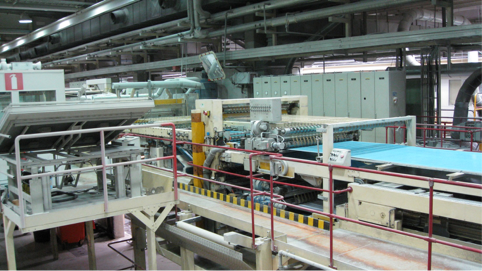

PRIMARY BELTS, TWO OVERLAPPING - AND SECONDARY BELT SECTIONS DUE TO FULL RUNNING SPEED IN PALLET CHANGE. THE DIVIDING GATE IS PRIOR TO THE OVERLAPPING.

THE END DELIVERY SECTION (LAYBOY)

DELIVERY CONVEYORS FOR FULL AND EMPTY PALLETS

THE CUTTER IS RUN FROM THE CONTROL ROOM

THE SPECIFIC INFO/MEASURES OF THE LINE

Length of the Sheet cutter: distance from the lay boy up to the first infeed roll: 20 meters

The unwinds 2 x EA v 2/1500 with preparation and auto loading (4 reels): 18 meters

The width of the line: 7 meters (cross width)

The height of the line: The height up to the head (crown) of a cutter man when standing on the service platform.: 3,850 mm

When the main electric cabinets are standing on the service platform.: 4,320 mm

The total width of the cutter head: 2,600 mm

The depth of the cutter head: 1,400 mm