Fact: Plastic Pollution in the World's Oceans. There are more than 5 Trillion Plastic Pieces Weighing over 250,000 Tons Afloat at Sea alone.

Typical Automatic Plastic Recycling Line

Plastic Crusher Features,

A, works with all granulators.

B, fully automatic material transfer, no laborer required.

C, stainless steel construction to assure material purity.

D, Dust-collecting devices incorporated, absorbing dust, preventing air pollution.

E, Simple disassembly for maintenance and cleaning.

Fact: Researchers say A total of 37.7 million pieces of plastic had washed up and spread out over Henderson Island. This is one place where we do know there to be a whole lot of plastic. Henderson Island is a deserted atoll in the middle of the southern Pacific Ocean. Research scientist Jennifer Lavers from the University of Tasmania led a recent expidition to the island, where the highest density of plastic waste anywhere on the planet was waiting for her. She estimates that a total of 37.7 million pieces had washed up and spread out over the uninhabited island, and that as many as 13,300 new pieces arrive every day.

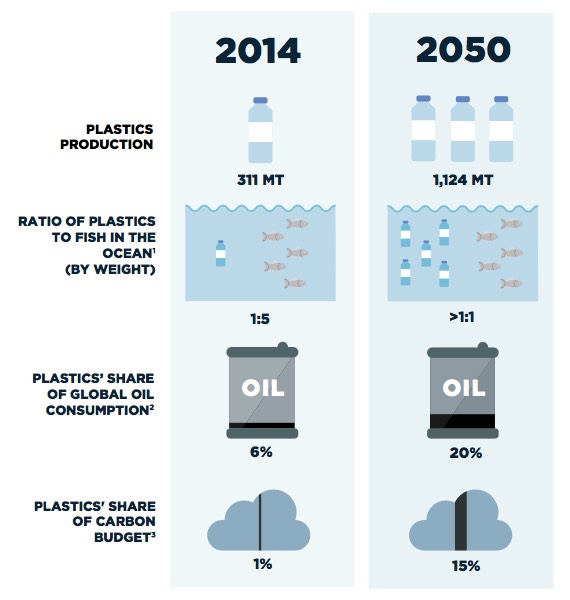

Fact: the global annual production of plastics in 2013 was 78million tons - and is expected to double over the next 20 years.

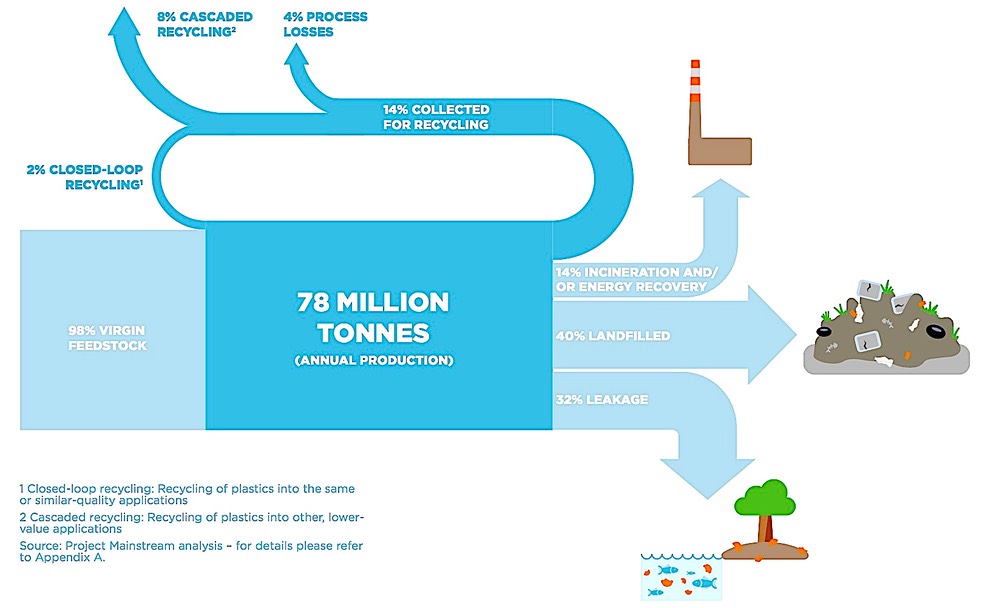

Fact: recycling accounts for only 14% of the waste. The rest hangs around for potentially hundreds of years.

Different types of recycling

A key principle of the circular economy is that products and materials are circulated at their highest value at all times (see Chapter 2 for more details). In the technical cycle, this implies that plastic packaging is reused when possible (circulating the packaging product), then recycled (circulating the packaging materials). Within recycling, this principle results in a general order of preference:

- Mechanical recycling in closed loops. This is the most value-preserving loop. Mechanical recycling keeps polymers intact and hence preserves more value than chemical recycling, where polymers are broken down. Closed-loop mechanical recycling keeps the quality of the materials at a similar level by cycling materials into the same application (e.g. from PET bottle to PET bottle) or into applications requiring materials of similar quality. As such, mechanical closed-loop recycling not only preserves the value of the material, it also maintains the range of possible applications in future, additional loops.

- Mechanical recycling in open loops (‘cascading’). Given the inherent quality loss during mechanical recycling,79 closed-loop mechanical recycling cannot continue inde nitely. Open-loop recycling plays an important role as well. In open-loop mechanical recycling, polymers are also kept intact, but the degraded quality and/or material properties require applications with lower demands. Cascading to the highest-value applications each cycle could help maximise value preservation and the number of possible loops.

- Chemical recycling. Chemical recycling breaks down polymers into individual monomers or other

hydrocarbon products that can then serve as building blocks or feedstock to produce polymers again.

As such, it is less value preserving than mechanical recycling. Chemical recycling technologies are not

yet widespread and/or not yet economically viable for most common packaging plastics. However,

as they could enable after-use plastics to be upcycled into virgin-quality polymers again, they could become an option for materials for which mechanical recycling is not possible (e.g. most multi-material packaging or plastics that cannot be cascaded any further).