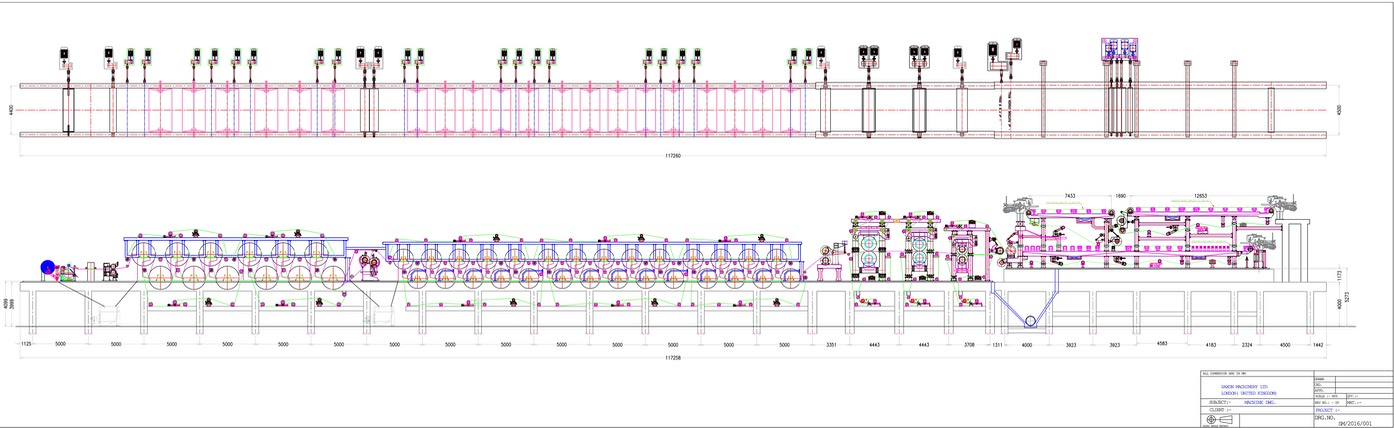

SMV0708 - 3,700mm trim Fourdriner Triple Layer Paper Machine for Kraft Test Liner

Sold “Turnkey" and with a 2 year guarantee

Technical Specifications

1 Finished Production : 250 TPD

2 Product Quality : Kraft Test Liner

3 Furnish : 65% OCC / 35% NDLKC

4 Type of Machine : Fourdriner multi layer Machine

5 Location : First Floor Machine

6 Trim width at Pope Reel : 3,700 mm

6.A Trim width (Finished Deckle) : 3,650 mm

7 Basis Weight Range : 120 - 350 gsm

8 Anchor G.S.M : 140 gsm

9 Designed Speed : 450 MPM

10 Operating Speed : 400 MPM Maximum

11 Machine Drive : A.C. Sectional / Silent Drive

12 Gross Production at Pope Reel : 277 M.T./ day Test Liner Kraft at 100% efficiency. Dryness of 95% at Pope Reeler.

13 Machine Efficiency : 90.0%

14 Finishing Loss : 3.0%

15 Net Saleable Production/day : 250.0 M.T./Day

16 Sole Plate Center : 4,500 mm ( Approx)

17 Web Shrinkage : 3.5% Maximum

18 Nominal Wire Width : 3,950 mm

19 Power Supply : As req’d

Frequency : As req’d

20 Compressed Air

21 Shower Water Pressure : H.P. Oscillating Shower: 22 - 25 Bar

: Low Pressure Shower: 4.0 Bar

: Water Line Pressure (Process): 2.5 - 3.0 Bar

22 Steam line Pressure : For Dryers: Maximum - 3.5 Bar

23 Maximum - Part Weight and Size

: Simple - Press Roll: 22 Ton

:Dia Meter : 1,370 dia

:Total Length: Approx 5100mm

24 Details For Calculation of Machine Deckle

:Type : Fourdriner multilayer Machine with Pressurized Head Box

:Pond Width (Slice Width): 3,800 mm

:Wire Width: 3,950 mm

:Sheet Width on Wire: 3,950 mm

:Wire Trims Total : 100 mm

:Sheet Width to Presses: 3,850 mm

:Press Trims Total: Nil

:Sheet Width to Dryers: 3,850 mm

:Shrinkage: 3.5%

:Sheet Width at Pope Reel: 3,700 mm

:Winder Trims Total: 50 mm

:Sheet Width After Winder: 3,650 mm

1 Pressurized Head Box (x 3)

2 WIRE SECTIONS

(a) Bottom Wire Part (Complete)

(b) Top Wire Part (Complete)

(c) Middle Wire Part (Complete)

3 PRESS SECTIONS

(a) First Press Section 950mm dia (Complete)

(b) Second Press Section 1,200mm dia (Complete)

(c) Third Press Section 1,370mm dia (Complete)

(d) Smoothing Press Section 900mm dia (Complete)

4 PRE Dryer Section 1,800mm X 4,002

5 Size Press With Kitchen (Complete)

6 Post Dryer 2,100mm dia X 4,002

7 Calander

8 Scanner

9 Pope Reel (Complete)

10 Rewinder (Complete)

11 Sectional Drive (35)

INDEX

S.R. BOX : Qty-1 No.

S.R. Box fabricated from 2mm thick S.S.- 304 with latest design in cylindrical shape with conical bottom having 3 nos. of nozzles, one is for inlet flow stock and 2nd one is fan pump inlet and 3rd one is for over flow of stock. Its special cylindrical shape and conical bottom does not allow any air entrapment and results uniform regulated flow of stock to Fan Pump avoiding grammage fluctuation in machine direction .

Centri Cleaner: (12 + 4 + 1 ) (1000 L.P.M.)

The centri cleaner consists of top cylindrical part made from 5mm thick S.S.- 304plate with tangential inlet and one vertical outlet. The outlet and inlet nozzle are provided with secondary M.S. loose flanges for easy assembly. A middle cone that is also made from 5mmthick S.S. -304 plate is connected to the top part. Below this a S.S.-fabricated cone is provided to resist the wear which is occurring mainly in this partition. With header & C.I. valve – 4” long plate and M.S. channel stand.

PRESSURE SCREEN : 1000 X 1000

Throughput : 130 TPD

Motor Rating : 40 HP X 1440 RPM

Operating Consistency : 0.8 – 1.2 %

Pressure drop across screen : 0.2 – 0.5 mwg

Screen Size : 1000 mm dia X 1000mm ht

Rotor Type : Multi Vane

Drive : Belt Drive

Slot Size : 0.35mm Slot

Bassket : SS – 316 L

BODY : S.S 304

PRESSURIZED HEAD BOX ( Closed Type )

Deckle ( Pond Width ) : 3800mm

Model : Closed Type Head Box ( Pressurized )

Type : Step Diffuser

G.S.M Range : 120 to 350 GSM

Machine Operating Speed : 400 Mts / minute

Operating Consistency : 0.6 to 8.0 %

Product : Kraft Paper

Top lip assembly movement : Worm gearbox

Top lip micro spindles movement : gear box with graduations

Movement of top lip towards machine direction : will provided

Material of Construction:

Head Box is made in SS 304 fabrication except the bottom stand . which is made in MS fabrication and provided with SS 304 sheet metal guard . The parts which are coming in contact with the pulp are made in SS 316 and 304 materials . Head box is provided with an inclined / vertical top slice attachment, which swivels on a hinge made in SS 304. The top slice arrangement is provided with total lifting and lowering arrangement ( Up to 75mm maximum ) and also with micro local adjustments . The head box is provided with cast Nylon Diffuser Bank of suitable size as required . The Head Box is also provided with head measuring Flexi glass tube system / Provision for installation of level transmitter for auto head control .

PULSATION CHAMBER is fabricated out of SS 304 material with dish end on the top and conical inlet at the bottom. The pulsation chamber is provided with Cast Nylon step diffuser ring between the cone and cylindrical portion . It is also provided with a cyclone air separator and outlet branch to suit the taper manifold .

TAPER DISTRIBUTION MANIFOLD is fabricated in SS 304 materials with suitable SS Stiffeners around it outside .The manifold is provided with two hinges with pneumatic cylinders to facilitate the manifold to during cleaning the manifold and the Head Box .

Scope of Supply :

Complete assembly unit with top slice lifting & lowering arrangement , Cast Nylon step Diffuser Bank and head measuring flexi – glass tube system . Pulsation chamber. Head Box Bottom Supporting legs .Our supply excludes electrical items .

FOURDRINIER WIRE PART 4,050 mm X 48 meter : 1 No

Breast Roll : 1 No

O.D. : 600 mm.

Face Length : 4050 mm.

Bearing Mounting Center : 4500 mm APX

Pipe : Seamless Pipe

Pipe O.D. : 560 mm

Pipe Thickness : 20 mm

Type of Covering : Black Diamond.

Coating Thickness : 20 mm

Bearing No : 22230 k

Make : FAG

Material of construction:

The breast roll shell is made out of Seamless steel Pipe having shell thickness 20 mm and gudgeons of cast iron. The end journals are of EN-8 steel and are press fitted with the shell. The breast roll is completely assembled and precision machined The breast roll is equipped with FAG roller bearings of no. 22230 ck and inserted into water tight bearing housing of cast iron with Laybrinth. The breast Roll lowering and lifting device Manually as per design

Wire Return Roll : 8 Nos

O.D. : 3,40mm with coating

Face Length : 4,050 mm.

Bearing Mounting CRS : 4,500 mm Apx

Pipe : Seamless Pipe

Pipe O.D. : 323 mm

Shell Thickness : 18 mm

Bearing No. : 22318 K, Make – FAG

Type of Coating : Ebonite Coating

Coating Thickness : 8.5 mm

Material of Construction:

The wire return roll shell is made out of prime quality seamless pipe having shell thickness 18 mm and gudgeons of cast iron. The end journals of EN-8 and cast iron gudgeons are press fitted with the shell. The wire return roll is completely assembled, dynamically balanced and precisionally machined/Ground for operating speed of 400 meters/min.

The wire return roll is equipped with FAG roller bearings having no.- 22318 K housing is provided with C.I. laybrinth.

Forming Board (1+2 Foils) : 1 No

Length of Elements : 4,050 mm

No. of Foils : 1+2 nos.

Nos. of Strips : 3

Foil Size : 200 mm wide - 1 no.

: 65 mm wide - 2 nos.

The forming board box will be fabricated out of 8 & 10 mm thick

S.S.-304 plate and 16 mm thick flat. The forming board box will have provision for the vertical and horizontal direction movement for optimum dewatering position. All the Ceramic elements fitted on the fiber T' bar fixing arrangement. Forming board is fix of on the wire table with help of S.S Studs.

Single Mono foil : Qty 10 Nos

Length of Elements : 4,050 mm

Width of Foil : 65 mm

The construction of mono foil is in 2.0mm S.S.-304Plate reinforced on M.S. ‘I’ Beam and top fitting pata will be S.S 304 75 X 16mm thick . The side fitting assembly will be S.S half round block with C.I mounting bracket .The heavy duty mono foil having the Ceramic T & Top fitting .Complete single mono foil machining , Drilling & Tapping as per our design .

Hydrofoil Box of 6 Foils : Qty 4 Nos

Length of Elements : 4,050 mm

No. of Foils in each box : 6 nos.

Width of Foil : 65 mm – 6 nos.

The hydrofoil box will be fabricated out of 5 & 10 mm thick S.S.-304 plate and 16 mm thick flat. The Hydrofoil box will have provision for the vertical and horizontal direction movement for optimum dewatering position. The tops elements shall be Ceramic Top with T bar fixing arrangement .

Ultra Low Vacuum Box Qty : 01 No.

Length of Elements : 4,050 mm

No of foils in each box : 9 nos

Width of Foil : 40 mm – 9 nos

Width of Box : 625 mm

Ultra Low Vacuum Box it will be fabricated from S.S. 304 5mm plate . Ultra Low Vacuum Box is fitted with Ceramic top of 40mmx40mm and these poly Ceramic are fitted on fiber ‘T’. S.S. studs 25mm will be provided to fix the ultra Low Vacuum Box on the wire table.

Low Vacuum Box Qty : 03 Nos.

Length of Elements : 4,050 mm

No of foils in each box : 6 nos

Width of Foil : 40 mm – 6 nos

Width of Box : 365 mm

Low Vacuum Box it will be fabricated from S.S. 304 5mm plate . Low Vacuum Box is fitted with Ceramic top of 40mmx40mm and these ceramic are fitted on fiber ‘T’. S.S. studs 25mm will be provided to fix the Low Vacuum Box on the wire table.

Suction Box : 6 Nos.

Length of Elements : 4,050 mm

Width of Top : 250 mm

Width of Box : 250 mm

Suction box will be fabricated from S.S.304, 5mm plate . As per our standard design .

S.S studs 25mm will be provided to fix the High Vacuum Box on the wire table

Auto Guide: 1 No

Type : Pneumatic operated type.

Auto Guide will be operated with Cylinder Type bellows.

The palm and senser elements shall be ceramics coated .

Wire Stretcher bellows Type : 3 Set

Stretcher fabricated in sand which plate & mounting plate will be S.S 304 with rubber bellows arrangement assembly .

Breast Roll Doctor: 01 No

Type : Stationary type.

Doctor holder body made out of M.S. Angle Box frame with S.S.-304 cladding with self weight loading. Doctor Holder frame vickery type K-35. Doctor Blade is made of synthetic (HDPE).

Wire Roll Doctor: 03 Nos

Type : Stationary type.

Doctor holder body made out of M.S. Angle Box frame with S.S.-304 cladding with self weight loading. Doctor Holder frame vickery type K-35. Doctor Blade is made of synthetic (HDPE). The doctor holder is provided with S.S.-304 Tray.

Wire Trays Single - Walled for white water: Complete

Made out of fabricated stainless Steel S.S.-304 for collection and discharge of white water from all dewatering elements with necessary supports etc. The wire tray shall be single walled thickness of wire tray plate shall be 2 mm & Supported with SS Squire pipe 40 X 40 X 2mm .

Wire Part Frame with Breast Roll Shake Frame: Complete

All Longitudinal and cross frames as well as cantilever beams are fabricated out of 16mm thick MS Plates and box type duly cladded with S.S. 304 Plate.

All matching parts are machined accurately to match the surface.

The main beams are provided with L& T System at the top for mounting the wire elements. The stands are made of M.S. with S.S. cladding.

There are removable spacers for mounting the wires. Cantilevering will be done by use of manually operated Screw with Nut which are mounted on operators side. With Shaking unit complete .

High Pressure Oscillating Shower : 01 No

The Shower is oscillating shower. The oscillating is done by geared motor and variable speed drive to be provided by the customer.

Type : Oscillating Type.

Type of Shower : Needle Jet.

Needle Size : 1.0 mm.

Nozzle Spacing : 150 mm

Stroke length : 300 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 20-22 Bar

The oscillating shower shall be complete with holding brackets and movable roller bracket etc.

Lubricating Shower : Qty 01 No

Type : Stationary.

Type of Shower : Fish Tail.

Nozzle Opening : 2.5 mm

Nozzle Spacing : 150 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 5-6 Bar

The stationary low pressure shower is fixed with brackets on both the sides and it has provision to adjust it in the angular direction.

Traveling & Fixed Trim Shower : Qty 01 No

Type : Mannual operating Type.

Nozzle Opening : 0.5 mm

The Fixed & trim squirts shower is made of S.S.-304 and is manual operating type, complete with S.S. fabricated supporting pipe frame, S.S. pipe and Moveable S.S block and complete in all respect.

Sheet Knock off Shower : Qty 01 No

Type of Shower : Fish Tail in S.S.-304

Nozzle Opening : 2.5 mm

Nozzle Spacing : 75 mm

Operating Pressure : 6-8 Bar

Pipe Size : 2" N.B., S.S.-304

The Sheet Knock of shower shall be complete with fixing brackets on both sides and it has provision to adjust it in the angular direction.

Sole Plate: Complete

The Sole plates are made out of cast iron construction and are rectangular in construction and precision ally machined on all the surfaces. The sole plate size shall be 350 mm wide x 75 mm thick. X 1500 mm lg.

Plate forms, Walk ways & Ladders: Complete

Plate forms, Walk ways & Ladders are included in our scope of supply & same shall be fabricated out of M.S. Angle iron, channel & Flat. The railing shall be fabricated out of 'A' class pipe and shall be epoxy painted.

Baggly Box – Qty 1 No

Manufactured out of S.S. Tube Machined Suitably and covered with Polypick Top. Necessary holder device is provided including connection for Vacuum. The pipe size shall be 6" N.B.

TOP WIRE PART 4050MM X 21MTR

1. S.R. BOX : Qty-1 No.

S.R. Box fabricated from 2mm thick S.S.- 304 with latest design in cylindrical shape with conical bottom having 3 nos. of nozzles, one is for inlet flow stock and 2nd one is fan pump inlet and 3rd one is for over flow of stock. Its special cylindrical shape and conical bottom does not allow any air entrapment and results uniform regulated flow of stock to Fan Pump avoiding grammage fluctuation in machine direction .

2. Centri Cleaner: ( 8+ 2 +1 )

(1000 L.P.M.)

The centri cleaner consists of top cylindrical part made from 5mm thick S.S.- 304plate with tangential inlet and one vertical outlet. The outlet and inlet nozzle are provided with secondary M.S. loose flanges for easy assembly. A middle cone that is also made from 5mm thick S.S. -304 plate is connected to the top part. Below this a S.S.-fabricated cone isprovided to resist the wearwhich is occurring mainly in this partition. With header &

C.I. valve – 4” long plate and M.S. channel stand.

3.PRESSURE SCREEN : 600 X 600

Description

Throughput : 70 TPD

Motor Rating : 90 HP X 1440 RPM

Operating Consistency : 0.8 – 1.2 %

Pressure drop across screen : 0.2 – 0.5 mwg

Screen Size : 600 mm dia X 600mm ht

Rotor Type : Multi Vane

Drive : Belt Drive

Slot Size : 0.35mm Slot

Bassket : SS – 316 L

BODY : S.S 304

4.a . PRESSURIZED HEAD BOX ( Closed Type )

Deckle ( Pond Width ) : 3800mm

Model : Closed Type Head Box ( Pressurized )

Type : Step Diffuser

G.S.M Range : 120 to 350 GSM

Machine Operating Speed : 400 Mts / minute

Operating Consistency : 0.6 to 8.0 %

Product : Kraft Paper

Top lip assembly movement : Worm gearbox

Top lip micro spindles movement : gear box with graduations

Movement of top lip towards machine direction : will provided

Material of Construction:

Head Box is made in SS 304 fabrication except the bottom stand . which is made in MS fabrication and provided with SS 304 sheet metal guard . The parts which are coming in contact with the pulp are made in SS 316 and 304 materials . Head box is provided with an inclined / vertical top slice attachment, which swivels on a hinge made in SS 304. The top slice arrangement is provided with total lifting and lowering arrangement ( Up to 75mm maximum ) and also with micro local adjustments . The head box is provided with cast Nylon Diffuser Bank of suitable size as required . The Head Box is also provided with head measuring Flexi glass tube system / Provision for installation of level transmitter for auto head control .

PULSATION CHAMBER is fabricated out of SS 304 material with dish end on the top and conicalinlet at the bottom. The pulsation chamber is provided with Cast Nylon step diffuser ring between the cone and cylindrical portion . It is also provided with a cyclone air separator and outlet branch to suit the taper manifold .

TAPER DISTRIBUTION MANI – FOLD is fabricated in SS 304 materials with suitable SS Stiffeners around it outside .The manifold is provided with two hinges with pneumatic Cylinders to facilitate the manifold to during cleaning the manifold and the Head Box .

Scope of Supply :

Complete assembly unit with top slice lifting & lowering arrangement , Cast Nylon step DiffuserBank and head measuring flexi – glass tube system . Pulsation chamber. Head Box Bottom Supporting legs .

(B) Breast Roll (Qty 1 No. Size Ø 540 x 4050mmface Length)

Breast roll fabricated from seamless pipe and having sale thickness of 20mm. The roll is having the shaft size of 170mm and bearing size of the roll will be 145mm. Roll is the dynamically balanced it will be the coated with Ebonite Coating.

(C) Helping Drive Roll (Qty 1 No. Size Ø 540x 4050mm face Length)

Helping Drive Roll fabricated from seamless pipe and having sale thickness of 20mm.

The roll is having the shaft size of 170mm and bearing size of the roll will be 145mm.

Roll is the dynamically balanced it will be the Fab Mat coated.

(D) Combination Roll (Qty 1 No. Size Ø 820x 4050mm face Length)

Combination roll fabricated from sandwich plate of 18 mm and having jacket system .

The roll is having bearing size of 145mm and O.D. of roll will be 820mm and face 4050mm.

The bearing housing is completed in all parts i.e. with deflector, covers and grease nipples.

The roll is completed machined. All the bearing size is grind finished.

(E) Wire Returns Rolls (Qty 3 No. Size Ø 340 x 4050mmface Length)

Wire returns roll will be seamless pipe having finish dia 340mm and shell thickness will be 18mm and rolls will be having the 2 Nos of M.S Gujjan fitting with En8 shaft. Roll will be Ebonite coated having the complete bearing fittings in all parts ie with deflector, covers and all roll will be dynamically balanced.

(F) Forming Board (Qty 1 No)

Forming board will be fabricated from S.S. 8mm plate and side plate will be 10mm plate all the inside supporting plate will be 8mm.All the Ceramic elements fitted on the ceramic‘T’. Which does 50x16mm S.S. flat support and the forming board is fix of on the wire table with help of S.S. studs.

(G) Foil Boxes (Qty 2 No.)

Foil box is having the 6 nos of the ceramic foils which are fitted with the Fiber ‘T’. Box is fabricated from S.S. 5mm plate. Which S.S. flat of size 40x16mm and internal supports will be by 5mm and side fittings plates will be 10mm and foil box up is fixed up on the wire table with S.S. studs of 25mm.

(H) Ultra Low Vacuum Box (Qty.1No.)

Constructions of U.L.V. Box top portion will be almost same but the design of U. L. V. Box lower portion will be quite different and also having the 9 nos. of Ceramic T and top.

(I) Low Vacuum Box (Qty. 02 No.)

The twin wire consist of 2 no. of Low Vacuum Box it will be fabricated from S.S. 304 5mm Plate having face 4050mm and width of each box will be 365mm and it is special designed for twin wire. The width of Low Vacuum Box will be varying as per position of Complete Low Vacuum Boxis fitted with Ceramic top of 40mmx40mm and these ceramic are fitted on fiber ‘T’. S.S. studs 25mm will be provided to fix the Low Vacuum Box on the wire table.

(J) Transfer Box : Qty-1No.

SS fabricated transfer box and top will be in ceramic coated . Complate Farication 8mm & .10mm Plate & 8mm support, in side 8mm support Plate. & Box Width 250mm.

(K) Auto Guide: (Qty 1 No):

Pneumatic Bellow Loaded Auto Guide with Ceramic coated sensor.

(L) H.P.Shower: Qty-1 No.

H.P shower Of 65mm dia SS shower pipe with needle jet type nozzles of 0.8mm size and having self cleaning system.

(M) Table Assembly:

Table assembly will be SS fabricated with SS fitting As per our design.

(N) Gear Box : 2 Nos

Helping drive & Combination roll Drive Gear box .

(O) Plateform & Railings.

Plateform and Railings will be fabricated from M.S. Plate and Pipes.

(P) S.S. Trays:

The complete tray will be fabricated from S.S. 304 plate 1.8mm and supported with S.S Squire Pipe 40X40X2mm.

(Q) Framing:

All framing will be fabricated from M.S 12 mm thick plate and will be cladded with S.S 304, 1.8 mm thick plate. All the mounting plates and Pad plates will be in 20mm (S.S -304) and 16mm. (S.S 304) complete frame will be machining as per requirement all the distance pieces will be in aluminum casting and Studs will be in S.S .

MIDDLE WIRE PART 4050MM X 31MTR

1. S.R. BOX : Qty-1 No.

S.R. Box fabricated from 2mm thick S.S.- 304 with latest design in cylindrical shape with conical bottom having 3 nos. of nozzles, one is for inlet flow stock and 2nd one is fan pump inlet and 3rd one is for over flow of stock. Its special cylindrical shape and conical bottom does not allow any air entrapment and results uniform regulated flow of stock to Fan Pump avoiding grammage fluctuation in machine direction .

2. Centri Cleaner: (1Set = 12+4 +1 Nos) (1000 L.P.M.)

The centri cleaner consists of top cylindrical part made from 5mm thick S.S.- 304plate with tangential inlet and one vertical outlet. The outlet and inlet nozzle are provided with secondary M.S. loose flanges for easy assembly. A middle cone that is also made from 5mm thick S.S. -304 plate is connected to the Middle part. Below this a S.S.-fabricated cone is provided to resist the wearwhich is occurring mainly in this partition. With header & C.I. valve – 4” long plate and M.S. channel stand.

3. PRESSURE SCREEN : 800 X800

Description

Throughput : 100 TPD

Motor Rating : 100 HP X 1440 RPM

Operating Consistency : 0.8 – 1.2 %

Pressure drop across screen : 0.2 – 0.5 mwg

Screen Size : 400 mm dia X 400mm ht

Rotor Type : Multi Vane

Drive : Belt Drive

Slot Size : 0.35mm Slot

Bassket : SS – 316 L

BODY : S.S 304

4.a . PRESSURIZED HEAD BOX ( Closed Type )

Deckle ( Pond Width ) : 3800mm

Model : Closed Type Head Box ( Pressurized )

Type : Step Diffuser

G.S.M Range : 120 to 350 GSM

Machine Operating Speed : 400 Mts / minute

Operating Consistency : 0.6 to 8.0 %

Product : Kraft Paper

Top lip assembly movement : Worm gearbox

Top lip micro spindles movement : gear box with graduations

Movement of top lip towards machine direction : will provided

Material of Construction:

Head Box is made in SS 304 fabrication except the bottom stand . which is made in MS fabrication and provided with SS 304 sheet metal guard . The parts which are coming in contact with the pulp are made in SS 316 and 304 materials . Head box is provided with an inclined / vertical top slice attachment, which swivels on a hinge made in SS 304. The top slice arrangement is provided with total lifting and lowering arrangement ( Up to 75mm maximum ) and also with micro local adjustments . The head box is provided with cast Nylon Diffuser Bank of suitable size as required . The Head Box is also provided with head measuring Flexi glass tube system / Provision for installation of level transmitter for auto head control .

PULSATION CHAMBER is fabricated out of SS 304 material with dish end on the top and conical inlet at the bottom. The pulsation chamber is provided with Cast Nylon step diffuser ring between the cone and cylindrical portion . It is also provided with a cyclone air separator and outlet branch to suit the taper manifold .

TAPER DISTRIBUTION MANIFOLD is fabricated in SS 304 materials with suitable SS Stiffeners around it outside .The manifold is provided with two hinges with pneumatic cylinders to facilitate the manifold to during cleaning the manifold and the Head Box .

Scope of Supply :

Complete assembly unit with top slice lifting & lowering arrangement , Cast Nylon step Diffuser Bank and head measuring flexi – glass tube system . Pulsation chamber. Head Box Bottom Supporting legs .Our supply excludes electrical items .

(B) Breast Roll (Qty 1 No. Size Ø 540 x 4050mmface Length)

Breast roll fabricated from seamless pipe and having sale thickness of 18mm. The roll is having the shaft size of 170mm and bearing size of the roll will be 145mm. Roll is the dynamically balanced it will be the coated with Ebonite Coating.

(C) Helping Drive Roll (Qty 1 No. Size Ø 540x 4050mm face Length)

Helping Drive Roll fabricated from seamless pipe and having sale thickness of 18mm. The roll is having the shaft size of 170mm and bearing size of the roll will be 145mm. Roll is the dynamically balanced it will be the Fab Mat coated.

(D) Combination Roll (Qty 1 No. Size Ø 820x 4050mm face Length)

Combination roll fabricated from sandwich plate of 18 mm and having jacket system .The roll is having bearing size of 145mm and O.D. of roll will be 820mm and face 4050mm. The bearing housing is completed in all parts i.e. with deflector, covers and grease nipples. The roll is completed machined. All the bearing size is grind finished.

(E) Wire Returns Rolls (Qty 4 No. Size Ø 340x4050mmface Length)

Wire returns roll will be seamless pipe having finish dia 340mm and shell thickness will be18mm and rolls will be having the 2 Nos of CI Gujjan fitting with En8 shaft. Roll will be Ebonite coated having the complete bearing fittings in all parts ie with deflector,covers and all roll will be dynamically balanced.

(F) Big Wire Returns Rolls (Qty 1 No. Size Ø 540x4050mmface Length)

Wire returns roll will be seamless pipe having finish dia 540mm and shell thickness will be 18mm and rolls will be having the 2 Nos of CI Gujjan fitting with En8 shaft. Roll will be Ebonite coated having the complete bearing fittings in all parts ie with deflector,covers and all roll will be dynamically balanced.

(G )Forming Board (Qty 1 No)

Forming board will be fabricated from S.S. 8mm plate and side plate will be 10mm plate all The inside supporting plate will be 8mm.All the ceramic elements fitted on the poly pick ‘T’. Which does 50x16mm S.S. flat support and the forming board is fix of on the wire table with help of S.S. studs.

(H) Foil Boxes (Qty 4 No.)

Foil box is having the 6 nos of the ceramic foils which are fitted with the Fiber ‘T’. Box is fabricated from S.S. 5mm plate. Which S.S. flat of size 40x16mm and internal supports will be by 5mm and side fittings plates will be 10mm and foil box up is fixed up on the wire table with S.S. studs of 25mm.

(I) Ultra Low Vacuum Box (Qty.2Nos.)

Constructions of U.L.V. Box top portion will be almost same but the design of U. L. V. Box lower portion will be quite different and also having the 9 nos. of poly picks T and top.

(J) Low Vacuum Box (Qty. 03 Nos.)

The middle wire consist of 2 no. of Low Vacuum Box it will be fabricated from S.S. 304 5mm Plate having face 4050mm and width of each box will be 365mm and it is special designed for middle wire. The width of Low Vacuum Box will be varying as per position of Complete Low Vacuum Box is fitted with Ceramic top of 40mmx40mm and these poly pick are fitted on fiber ‘T’. S.S. studs 25mm will be provided to fix the Low Vacuum Box on the wire table.

(K) Transfer Box : Qty-1No.

SS fabricated transfer box and top will be in ceramic coated . Complate Farication 8mm & .10mm Plate & 8mm support, in side 8mm support Plate. & Box Width 250mm.

(L) Auto Guide: (Qty 1 No):

Pneumatic Bellow Loaded Auto Guide with Ceramic coated sensor.

(M) H.P.Shower: Qty-1 No.

H.P shower Of 65mm dia SS shower pipe with needle jet type nozzles of 0.8mm size and having self cleaning system.

(N) Table Assembly:

Table assembly will be SS fabricated with SS fitting As per our design.

(O) Gear Box : 2 Nos

Helping drive & Combination roll Drive Gear box .

(P) Plateform & Railings.

Plateform and Railings will be fabricated from M.S. Plate and Pipes.

(Q) S.S. Trays:

The complete tray will be fabricated from S.S. 304 plate 1.8mm and supported with S.S Squire Pipe 40X40X2mm.

(R) Framing:

All framing will be fabricated from M.S 12 mm thick plate and will be cladded with S.S 304, 1.8 mm thick plate. All the mounting plates and Pad plates will be in 20mm (S.S -304) and 16mm. (S.S 304) complete frame will be machining as per requirement all the distance pieces will be in aluminum casting and Studs will be in S.S .

3(A) PRESS SECTION:

1st Press BDL & TOP Felting With pick up arrangement :

Press Roll : 2 Nos

Size : dia 950 mm x 3950 mm face

Shell Material : MS

Shell thickness : 50- 60 mm

Covering : BDL

Lining Thickness : 25 mm

Journal diameter : 220mm

Bearing No : 23248K

Make : FAG

The 1st press Top & Bottom roll is made out of MS seamless pipe having shell thickness 50-60 mm. The MS Shell is machined from inside as well

The Top & Bottom press roll is equipped with FAG roller bearings having No. 23248 k inserted into water tight bearing . The Top roll will be dynamically balanced at the 500 MPM . The roll will be BDL coated .

Felt Rolls for Press Section : 13 Nos

O.D. : 290 mm.

Face Length : 3950 mm.

Bearing No. : 22316 K FAG

Type of Coating : Ebonite Coating

Shell Thickness : 16 mm.

Shell Material : Seamless Pipe

Shaft & Journal : EN-8

Material of Construction:

The Press Felt roll shell is made out of prime quality seamless pipe having shell thickness 16 mm and gudgeons of cast iron. The end journals of EN-8 and cast iron gudgeons are press fitted with the shell. The press felt roll is completely assembled, dynamically balanced and precision ally machined/Ground for operating speed of 400 meters/min. The felt roll is equipped with FAG bearings having no. 22316 k inserted into water tight bearing housing of cast iron with C.I. labyrinth.

Auto Guide: Qty 2 Nos

Type : Pneumatic operated type.

Auto Guide will be operated by pneumatic bellows.

The palm and senser elements shall be ceramics coated .

Paper Transfer Roll: Qty 2 Nos

Size: dia 141 mm x 3950 mm face length

The paper transfer roll is manufactured out of M.S. pipe having shell thickness 12 mm fitted with end journals of EN-8, Machined accurately, dynamically balanced and assembled with roller bearings including C.I. bearing housings. The outer surface of the paper transfer roll is covered with chrome plating having thickness 100 microns.

Uhle Box: Qty 2 Nos

Slot width : 12 mm

Manufactured out of S.S 304 tube, machined suitably and equipped with single slot equipped with Polypick –T & Tops . Necessary holder device is provided including connection for vacuum.

The Pipe Size shall be 6" N.B.

Anti Blow Box for Presses: Qty 1 No

Slot width : 10.0 mm

Manufactured out of S.S 304 tube, machined suitably and equipped with single slot equipped with Polypick T & Tops and Plastic 'T' bars.

Necessary holder device is provided including connection for vacuum. The Pipe Size shall be 6" N.B.

Felt Stretcher (Motorized ): Qty 2 Nos

Stretcher made in S.S.304 ,4” dia pipe with bronz gear & worm shaft with C.I Gear box body .

Stretcher spindle made in S.S 304 , 40 dia shaft with Gun metal nut .

Motorized adjustment will be provided at the operator side CI hand wheel for drive .

High Pressure Oscillating Shower : Qty 2 Nos

The Shower is oscillating shower. The oscillating is done by geared motor and variable speed drive to be provided by the customer.

Type : Oscillating Type.

Type of Shower : Needle Jet.

Needle Size : 1.0 mm.

Nozzle Spacing : 150 mm

Stroke length : 300 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 20-22 Bar

The oscillating shower shall be complete with holding brackets and movable roller bracket etc.

Lubricating Shower : Qty 2 Nos

Type : Stationary.

Type of Shower : Fish Tail.

Nozzle Opening : 2.5 mm

Nozzle Spacing : 150 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 5-6 Bar

The stationary low pressure shower is fixed with brackets on both the sides and it has provision to adjust it in the angular direction.

Save all Trays: Qty 2 Nos

Made out of fabricated stainless Steel S.S.-304 for collection and discharge of white water from Press Bottom Rolls with necessary supports etc.

Press Frames : Complete

Complete press frame will be fabricated from MS16, 20 mm thick plate .Lever will be fabricated from MS 16mm thick plate with G.M.Bush fitting & S.S Pin . Complete framing fabrication machining & Drilling Tapping as per our design . All Framing cladded with S.S 304 , 1.5 mm thk plate & Mounting plate will be S.S 304 .

Sole Plate for Press Section: Complete

Size of Sole Plate: 350 mm w x 75 mm thick x 1500 mm lg.

The Sole plates are made out of cast iron construction and are rectangular in construction and precisionally machined on all the Surfaces and having 4 no.of jack tapping.

Walk Ways and Plate forms: Complete

Platforms, Walk ways & Ladders are included in our scope of supply & same shall be fabricated out of M.S. Angle iron, channel & Flat. The railing shall be fabricated out of 'A' class pipe and shall be epoxy painted.

Hydraulic Cylinder Loading & Control System with Common Control Panel: Complete

Hydraulic cylinders of suitable capacity with flow and pressure control system for individual cylinders will be provided on a common operation desk for easy &safe operation of press part and it's felt run.

The Penumatic Power Pack is also included in our scope of supply ,

3(B) 2nd Press BD Roll With Top Felting :

Press Roll : 2 Nos

Size : dia 1200mm x 3950 mm face

Shell Material : Steel Cast

Shell thickness : 100 – 110 mm

Covering : BDL

Lining Thickness : 20 mm

Journal diameter : 320 mm

Bearing No : 23264 K

Make : FAG

The 1st press Top & Bottom roll is made out of Steel cast pipe havings hell thickness 100 -110 mm. The Steel cast Shell is machined from inside as well. The Top & Bottom press roll is equipped with FAG roller bearings having No. 23264 k inserted into water tight bearing . The Top roll will be dynamically Balanced at the 500 MPM . The roll will be BDL coated .

Felt Rolls for Press Section: 13 Nos

O.D. : 290 mm.

Face Length : 3950 mm.

Bearing No. : 22316 K FAG

Type of Coating : Ebonite Coating

Shell Thickness : 16 mm.

Shell Material : Seamless Pipe

Shaft & Journal : EN-8

Material of Construction:

The Press Felt roll shell is made out of prime quality seamless pipe having shell thickness 16 mm and gudgeons of cast iron. The end journals of EN-8 and cast iron gudgeons are press fitted with the shell. The press felt roll is completely assembled, dynamically balanced and precisionally machined/Ground for operating speed of 500 meters/min.

The felt roll is equipped with FAG bearings having no. 22316 K inserted into water tight bearing housing of cast iron with C.I. laybrinth.

Auto Guide: Qty 2 No

Type : Pneumatic operated type.

Auto Guide will be operated by Pneumatic Cylinder with.

The palm and senser elements shall be ceramics coated ..

Paper Transfer Roll: Qty 1 No

Size: dia 165 mm x 3950 mm face length

The paper transfer roll is manufactured out of M.S. pipe having shell thickness 12 mm fitted with end journals of EN-8, Machined accurately, dynamically balanced and assembled with roller bearings including C.I. bearing housings. The outer surface of the paper transfer roll is covered with chrome plating having thickness 100 microns.

Uhle Box: Qty 2 Nos

Slot width : 12 mm

Manufactured out of S.S 304 tube, machined suitably and equipped with single slot equipped with Polypick –T & Tops

Necessary holder device is provided including connection for vacuum.

The Pipe Size shall be 6" N.B.

Felt Stretcher (Motorized): Qty 2 Nos

Stretcher made in S.S.304 ,4” dia pipe with bronz gear & worm shaft with C.I Gear box body .

Stretcher spindle made in S.S 304 , 40 dia shaft with Gun metal nut .

Motorized adjustment will be provided at the operator side CI hand wheel for drive .

High Pressure Oscillating Shower : Qty 2 Nos

The Shower is oscillating shower. The oscillating is done by geared motor and variable speed drive to be provided by the customer.

Type : Oscillating Type.

Type of Shower : Needle Jet.

Needle Size : 1.0 mm.

Nozzle Spacing : 150 mm

Stroke length : 300 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 20-22 Bar

The oscillating shower shall be complete with holding brackets and movable roller bracket etc.

Lubricating Shower: Qty 2 Nos

Type : Stationary.

Type of Shower : Fish Tail.

Nozzle Opening : 2.5 mm

Nozzle Spacing : 150 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 5-6 Bar

The stationary low pressure shower is fixed with brackets on both the sides and it has provision to adjust it in the angular direction.

Save all Trays: Qty 2 Nos

Made out of fabricated stainless Steel S.S.-304 for collection and discharge of white water from Press Bottom Rolls with necessary supports etc.

Press Frames : Open Type Complete

Compete press frame will be fabricated from MS 16,25 & 40 mm Thick plate & Clading 1.8 mm ,S.S 304 .Lever will be fabricated from MS 20mm thick plate with G.M.Bush Fiting & S.S Pin . Complete framing fabrication machining & Drilling Tapping as per our desgn

Sole Plate for Press Section: Complete

Size of Sole Plate: 350 mm w x 75 mm thick x 1500 mm lg.

The Sole plates are made out of cast iron construction and are rectangular in construction and precisionally machined on all the Surfaces and having 4 no.of jack tapping.

Walk Ways and Plate forms: Complete

Plate forms, Walk ways & Ladders are included in our scope of supply & same shall be fabricated out of M.S. Angle iron, channel & Flat. The railing shall be fabricated out of 'A' class pipe and shall be epoxy painted.

Hydraulic Cylinder Loading & Control System with Common Control Panel: Complete

Hydraulic cylinders of suitable capacity with flow and pressure control system for individual cylinders will be provided on a common operation desk for easy &safe operation of press part and it's felt run.

The Penumatic Power Pack is also included in our scipe of supply ,

3 (C) 3rd Press BD Roll With Top Felting :

Press Roll : 2 Nos

Size: dia 1370mm x 3900 mm face

Shell Material : steel cast

Shell thickness : 110 – 120 mm

Covering : BDL

Lining Thickness: 25 mm

Journal diameter: 360 mm

Bearing No: 23272 K

Make: FAG

The 3rd press Top & Bottom roll is made out of steel cast pipe havingshell thickness 110 -120 mm. The Steel cast Shell is machined from inside as well The Top & Bottom press roll is equipped with FAG roller bearings having No. 23272 k inserted into water tight bearing . The Top roll will be dynamically Balanced at the 500 MPM . The roll will be BDL coated .

Felt Rolls for Press Section: 13 Nos

O.D. : 290 mm.

Face Length : 3950 mm.

Bearing No.: 22316 K FAG

Type of Coating : Ebonite Coating

Shell Thickness : 16 mm.

Shell Material: Seamless Pipe

Shaft & Journal: EN-8

Material of Construction:

The Press Felt roll shell is made out of prime quality seamless pipe having shell thickness 15.1 mm and gudgeons of cast iron. The end Journals of EN-8 and cast iron gudgeons are press fitted with the shell. The press felt roll is completely assembled, dynamically balanced and precisionally machined/Ground for operating speed of 400 meters/min. The felt roll is equipped with FAG bearings having no. 22316 K inserted into water tight bearing housing of cast iron with C.I. laybrinth.

Auto Guide: Qty 2 Nos

Type : Pneumatic operated type.

Auto Guide will be operated by pneumatic Cylinder with.

The palm and senser elements shall be ceramics coated ..

Paper Transfer Roll: Qty 1 No

Size: dia 141 mm x 3950 mm face length

The paper transfer roll is manufactured out of M.S. pipe having shell thickness 12 mm fitted with end journals of EN-8, Machined accurately, dynamically balanced and assembled with roller bearings including C.I. bearing housings. The outer surface of the paper transfer roll is covered with chrome plating having thickness 100 microns.

Uhle Box: Qty 2 Nos

Slot width : 12 mm

Manufactured out of S.S 304 tube, machined suitably and equippedwith single slot equipped with Polypick –T & Tops .

Necessary holder device is provided including connection for vacuum.

The Pipe Size shall be 6" N.B.

Felt Stretcher (Motorized): Qty 2 Nos

Stretcher made in S.S.304 ,4” dia pipe with bronz gear & worm shaft with C.I Gear box body .

Stretcher spindle made in S.S 304 , 40 dia shaft with Gun metal nut .

Motorized adjustment will be provided at the operator side CI hand wheel for drive

High Pressure Oscillating Shower : Qty 2 No

The Shower is oscillating shower. The oscillating is done by geared motor and variable speed drive to be provided by the customer.

Type : Oscillating Type.

Type of Shower : Needle Jet.

Needle Size : 1.0 mm.

Nozzle Spacing : 150 mm

Stroke length : 300 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 20-22 Bar

The oscillating shower shall be complete with holding brackets and movable roller bracket etc.

Lubricating Shower: Qty 2 Nos

Type : Stationary.

Type of Shower : Fish Tail.

Nozzle Opening : 2.5 mm

Nozzle Spacing : 150 mm

Pipe : 2" N.B. S.S. -304.

Operating Pressure : 5-6 Bar

The stationary low pressure shower is fixed with brackets on both the sides and it has provision to adjust it in the angular direction.

Save all Trays: Qty 2 Nos

Made out of fabricated stainless Steel S.S.-304 for collection and discharge of white water from Press Bottom Rolls with necessary supports etc.

Press Frames : Open Type Complete

Compete press frame will be fabricated from MS 20, 30 mm Thick plate .Lever will be fabricated from MS 30mm thick plate with G.M.Bush Fitting & S.S Pin . Complete framing fabrication machining & Drilling Tapping as per our design . All Framing cladded with S.S 304 , 1.8 mm thk .

Sole Plate for Press Section: Complete

Size of Sole Plate: 350 mm w x 75 mm thick x 1500 mm lg.

The Sole plates are made out of cast iron construction and are rectangular in construction and precisionally machined on all the Surfaces and having 4 no.of jack tapping.

Walk Ways and Plate forms: Complete

Plate forms, Walk ways & Ladders are included in our scope of supply & same shall be fabricated out of M.S. Angle iron, channel & Flat. The railing shall be fabricated out of 'A' class pipe and shall be epoxy painted.

Hydraulic Cylinder Loading & Control System with Common Control Panel: Complete

Hydraulic cylinders of suitable capacity with flow and pressure

control system for individual cylinders will be provided on a common

operation desk for easy &safe operation of press part and it's felt run.

The Penumatic Power Pack is also included in our scipe of supply ,

3 (D) Smoothing Press

Press Roll : 2 Nos

Size : dia 900mm x 3900 mm face

Shell Material : M.S Pipe

Shell thickness : 20 mm

Covering : Chrome / Ebonite

Lining Thickness : 20 mm ( Ebonite )

Bearing Make : FAG

The Smoothing press Top & Bottom roll is made out of M.S pipe having shell thickness 20 mm. The Steel cast Shell is machined from inside as well The Top & Bottom press roll is equipped with FAG roller bearings inserted into water tight bearing . The Top & Bottom roll will be dynamically Balanced at the 500 MPM . The Top & bottom roll will be Chrom / Ebonite coated .

Press Frames : Open Type Complete

Compete press frame will be fabricated from MS 16, 20 & 32 mm Thik plate .Lever will be fabricated from MS 30mm thick plate with G.M.Bush Fiting & S.S Pin . Complete framing fabrication machining & Drilling Tapping as per our design . All Framing cladded with S.S 304 , 1.8 mm thick

Sole Plate for Press Section: Complete

Size of Sole Plate: 350 mm w x 75 mm thick x 1500 mm lg.

The Sole plates are made out of cast iron construction and are rectangular in construction and precision machined on all the surfaces and having 4 no.of jack tapping.

Walk Ways and Plate forms: Complete

Plate forms, Walk ways & Ladders are included in our scope of supply & same shall be fabricated out of M.S. Angle iron, channel & Flat. The railing shall be fabricated out of 'A' class pipe and shall be epoxy painted.

Hydraulic Cylinder Loading & Control System with Common Control Panel: Complete

Hydraulic cylinders of suitable capacity with flow and pressure control system for individual cylinders will be provided on a common operation desk for easy &safe operation of press part and it's felt run. The Penumatic Power Pack is also included in our scipe of supply ,

4. Pre-Dryer Section:

Drying Cylinder : 28 Nos

Diameter : 1800 mm

Face Length : 4000 mm.

Bearing Size : 23044 k

Make : FAG

Shell Thickness : 25 to 28 mm.

Hardness of Shell : HB 190 – 220

Maximum Operating Pressure : 5 Kg

Maximum Hydraulic Test Pressure : 8 Kg

The drying cylinder shell is manufacture out of Graded cast iron GG30 having shell Thickness 25-28 mm after machining and

grinding on out side as well as in side. with Bolted end covers duly assembled, dynamically balanced to run at 600 meter/ min. Hydraulically Pressure tested and journals equipped with roller bearings and bearing housing suitable for Dryer and COL System with Hood , Carrier Rope Arrangement

Felt Rolls:

Diameter : 290 mm

Face : 3,950 mm

Bearing Mounting CRS : 4,500 mm APX

Pipe O.D. : 273 mm

Pipe Thickness : 16 mm

Bearing No. : 22316 k, Make: FAG

Type of Covering : Ebonite

Coating Thickness : 8.5 mm

Shaft Journal : EN-8

The felt rolls made of seamless steel pipe having shell thickness 16 mm The cast iron dummy and EN-8 Journals are press fitted and assembled with the pipe by press fitting. The roll is machined accurately and dynamically balanced to run at 500 meter/ min.and assembled with roller bearings including C.I. bearing housings. The outer surface of the felt roll is covered with wear-resistance Ebonite coating.The felt roll C.I bearing housing housings shall be provided with Complete .

Drive Rolls:

Diameter : 340 mm

Face : 3,950 mm

Bearing Mounting CRS : 4,500 mm APX

Pipe O.D. : 323 mm

Pipe Thickness : 18 mm

Bearing No. : 22318 k, Make: FAG

Type of Covering : Ebonite

Coating Thickness : 8.5 mm

Shaft Journal : EN-8

The drive rolls are made of seamless steel pipe having shell thickness 16 mm The cast iron dummy and EN-8 Journals are press fitted and assembled with the pipe by press fitting. The roll is machined accurately and dynamically balanced to run at 500 meter/ min.and assembled with roller bearings including C.I. bearing housings. The outer surface of the drive roll is covered with wear-resistance Ebonite coating.

The felt roll C.I bearing housing housings shall be provided Complete .

Dryer Fixed Doctors:

The fixed doctor body are made of mild steel angle heavy dutytype, complete with eccentric cam. Holding bracket etc. to be fixed with the frame. The doctor holder is K-35 type and doctor blade is of phosphor Bronze. The doctor holder lifting / lowering is done byOur design .

Auto Guide :

Type : Pneumatic operated type.

Auto Guide will be operated by pneumatic Cylinder with.

The palm and senser elements shall be ceramics coated ..

Felt Stretcher (Motorized):

Stretcher made in S.S.304 ,4” dia pipe with bronz gear & worm shaft with C.I Gear box body . Stretcher spindle made in S.S 304 , 40 dia shaft with Gun metal nut .

Motorized adjustment will be provided at the operator side CI hand wheel for drive .

Heavy duty Frames:

M.S. Fab frame Box in construction, machined to the required tolerances.

The frames are pre-assembled at factory and match marked for easy erection at the site. The frame are Grinding and two coats of painting will be done prior to dispatch. All the frame are provided with required size high tensile assembly Nuts & Bolts. The dryer frames shall be complete with Tie Rod etc.

Sole Plate:

The Sole plates are made out of cast iron construction and arerectangular in construction and precisionally machined on all the surfaces. The sole plates are complete with grouting Bolts and jack bolts etc. of high tensile. The sole plate size shall be 360 mm wide size x 75mm thick. X 1500 mm lg. The sole plates are 'T' slot type. The sole plate 'T' bolts are included in our scope of supply.

Paper Transfer Roll (Chrome Roll):

Size: dia 165 mm x 3950 mm face length

The paper transfer roll is manufactured out of semaless steel pipe having shell thickness 12 mm fitted with end journals of EN-8, Machined accurately, dynamically balanced and assembled with roller bearings including C.I. bearing houisngs. The outer surface of the paper transfer roll is covered with chrome plating having thickness 100 microns. The paper transfer roll shall be provided with flat pully for separate mechanical drive.

Walkways & Platform:

Plate forms, Walk ways are included in our scope of supply & same shall be fabricated out of M.S. Channel, M.S. Angle iron, M.S. Flat and railings shall be of pipes. The walkways, ladders & railings shall be epoxy painted.

5. SIZE PRESS:

The Size Press shall be with the following Parameters:

Dryness of the Paper Entering Size Press (Assumed) : 90 to 92%

Size Pickup per side : 1.0 to 1.5gsm.

Dryness of Paper Leaving Size Press : 70 to 72%

Concentration of Size Solution : 8- 10%

Mill air pressure Required : 5.0Kgs/Cm²

The Size Press shall be with the following Accessories:

Size Press Roll: 2 Nos

Size : dia 800 mm x 3950 mm face length.

Manufactured out of M.S. Pipe having 38-40mm thickness with press fitted C.I. hubs and EN-8 journals, machined accurately & assembled with antifriction roller bearings including bearing housing and covers. One roll outer surface will be rubber/ Micro rock covered with suitable hardness. and the other roll outer diameter shall be coated with 100 ± 1° share Ahardness with better sheet releasing property.

Chrome Roll:

Size: Dia. 273 mm x 3950 mm face length

Manufactured out of M.S Pipe having 15-16mm thickness with press fitted C.I. hubs and EN-8 journals, machined accurately & assembled with antifriction roller bearings including bearing housing and covers. The outer surface with be having chrome plating 100 microns.

Paper In feed Roll:

Size : dia 290 mm x 3950 mm face length.

Manufactured out of mild steel tube shrink fitted with end journals, machined accurately and assembled with antifriction roller bearings including cast iron bearing housing. The roll outer surface will be chrome plated having chrome thick. 100 microns.

Frame:

The frame for size press shall be made out of mild steel fabricated box type construction with pivot for fixing the loading cylinder etc. duly painted and side fixing arrangement for S.S. tray. All framing will be cladded with S.S 304 ,1.8 mm thk plate.

Side End Shield Over Flow Funnel:

A suitable side end shield made out of S.S.-304 and over flow funnels of S.S. 304

Size Spray Pipe:

Made out of stainless steel pipe with spray nozzle to be fixed above the roll valve. The scrapper and funnels are fixed at either side of the roll for exess collection.

Cross Plate from and Rails:

The cross plate from walkway shall be fabricated out of M.S. angleiron and ladders shall be mild steel duly galvinised.

Sole Plate:

The sole plates are made out of cast iron construction and are rectangular in construction and precisionally machined on all the surfaces. The sole plates are complete with grouting Bolts and jack bolts etc. of high tensile. The sole plate size shall be 360 mm wide size x 75 mm thick x 1500 mm lg. The sole plates are T slot type. The sole plate High Tensile bolts are included in our scope of supply.

SIZE KITCHEN

SIZE COOKER 3 m3

Cooker fabricated from S.S 304 , 5mm thickness plate with dish bottom and fitted with the one no of agitator . Agitator made from S.S. vanes and EN8 shaft dia will be 60mm and one no of bearing housing , having 2 nos. of bearing and V- Belt 2 groove pulley. 10 HP X 960 RPM motor is required to drive the agitator . Cooker capacity will be 3,000 ltr. The vessel will be jacketed for indirect steam heating arrangement.

STORAGE TANK 5 m3 :

Storage tank fabricated from S.S 304 , 3mm thickness plate with 3 mm thick dish bottom . Storage tank shall be fitted with the one no of agitator . Agitator made from S.S vanes and EN-8 shaft dia will be 60mm and one no of bearing housing having 2 nos. of bearing and one V- Belt 2 groove pulley. 10 HP X 960 RPM motor is required to drive the agitator. Storage tank capacity will be 5000ltr. The vessel will be provided with 1” dia. steam coil for heating the starch solution.

SERVICE TANK 5 m3 :

Service tank fabricated from S.S 304 , 3mm thickness plate with 3 mm thick dish bottom . Storage tank shall be fitted with the one no of agitator . Agitator made from S.S vanes and EN-8 shaft dia will be 60mm and one no of bearing housing having 2 nos. of bearing and one V- Belt 2 groove pulley. 10 HP X 960 RPM motor is required to drive the agitator. Storage tank capacity will be 5000ltr. The vessel will be provided with 1” dia. steam coil for heating the starch solution.

Over Flow Tank – 1.2 m3

S.S. fabricated tank with 3mm thick plate’s shell and 5mm thick dish bottom.

Vibro Screen - 1200 dia vibro screen with 40 mesh fabric .

Progressive Cavity (Single Screw) Pumps : 3 Nos.

7. Post Dryer Section:

Drying Cylinder : 10+2 Nos

Diameter : 1800 mm

Face Length : 4,000 mm

Bearing Make : FAG

Shell Thickness : 25 to 28 mm.

Hardness of Shell : HB 190 – 220

Maximum Operating Pressure : 5 Kg

Maximum Hydraulic Test Pressure : 8 Kg

The drying cylinder shell is manufacture out of Graded cast iron GG 30 having shell Thickness 25-28 mm after machining and grinding on out side as well as in side. with Bolted end covers duly assembled, dynamically balanced to run at 600 meter/ min. Hydraulically Pressure tested and journals equipped with roller bearings and bearinghousing suitable for dryer & COL System With Hood , Carrier Rope System With.Penumatic System .

Dryers (Chrome Coated) , 2 Nos Coating will be 0.1 mm to 0.3 mm

Felt Rolls:

Diameter : 290 mm

Face : 3950 mm

Bearing Mounting CRS : 4400 mm

Pipe : Seamless Pipe

Pipe O.D. : 273 mm

Pipe Thickness : 15 mm

Pipe Schedule : 80

Bearing No. : 22316 K,

Make : FAG

Type of Covering : Ebonite

Coating Thickness : 8.5 mm

Shaft Journal : EN-8

The felt rolls made of seamless steel pipe having shell thickness 15.1 mm The cast iron dummy and EN-8 Journals are press fitted and assembled with the pipe by press fitting. The roll is machined accurately and dynamically balanced to run at 500 meter/ min .and assembled with roller bearings including C.I. bearing housings. The outer surface of the felt roll is covered with wear-resistance Ebonite coating.

The felt roll C.I bearing housing shall be provided complete assembly .

Drive Rolls:

Diameter : 340 mm

Face : 3950 mm

Bearing Mounting CRS : 4400 mm

Pipe : Seamless Pipe

Pipe O.D. : 323 mm

Pipe Thickness : 18 mm

Bearing No. : 22318 K,

Make : FAG

Type of Covering : Ebonite

Coating Thickness : 8.5 mm

Shaft Journal : EN-8

The drive rolls made of seamless steel pipe having shell thickness 18 mm The cast iron dummy and EN-8 Journals are press fitted and assembled with the pipe by press fitting. The roll is machined accurately and dynamically balanced to run at 500 meter/ min .and assembled with roller bearings including C.I. bearing housings. The outer surface of the drive roll is covered with wear-resistance Ebonite coating.

Dryer Fixed Doctors:

The fixed doctor body are made of mild steel angle heavy duty type, complete with eccentric cam. Holding bracket etc. to be fixed with the frame. The doctor holder is K-35 type and doctor blade is of phosphor Bronze. The doctor holder lifting / lowering is done by our design .

Auto Guide :

Type : Pneumatic operated type.

Auto Guide will be operated by pneumatic bellows with.

The palm and senser elements shall be ceramics coated ..

Felt Stretcher (Manual):

Stretcher made in S.S.304 ,4” dia pipe with bronz gear & worm shaft with C.I Gear box body . Stretcher spindle made in S.S 304 , 40 dia shaft with Gun metal nut .

Manual adjustment will be provided at the operator side CI hand wheel for drive .

Heavy duty Frames:

M.S. Fab frame Box in construction, machined to the required tolerances. The frames are pre-assembled at factory and match marked for easy erection at the site. The frame are Grinding and two coats of painting will be done prior to dispatch. All the frame are provided with required size high tensile assembly Nuts & Bolts. The dryer frames shall be complete with Tie Rod etc.

Sole Plate:

The Sole plates are made out of cast iron construction and are rectangular in construction and precisionally machined on all the surfaces. The sole plates are complete with grouting Bolts and jack bolts etc. of high tensile. The sole plate size shall be 360 mm wide size x 75mm thick. X 1500 mm lg. The sole plates are 'T' slot type. The sole plate 'T' bolts are included in our scope of supply.

Paper Transfer Roll (Chrome Roll):

Size: dia 165 mm x 3950 mm face length

The paper transfer roll is manufactured out of semaless steel pipe having shell thickness 12 mm fitted with end journals of EN-8, Machined accurately, dynamically balanced and assembled with roller bearings including C.I. bearing houisngs. The outer surface of the paper transfer roll is covered with chrome plating having thickness 100 microns. The paper transfer roll shall be provided with flat pully for separate mechanical drive.

Walkways & Platform:

Plate forms, Walk ways are included in our scope of supply & same shall be fabricated out of M.S. Channel, M.S. Angle iron, M.S. Flat and railings shall be of pipes. The walkways, ladders & railings shall be epoxy painted.

7. CALANDER ( 3950 mm Face Length)

The Single Nip two –roll calendar consists of mainly following parts :

- Top chilled C.I .roll of 450 mm diameter .

- One bottom rolls of chilled C.I. of 600 mm diameter .

- Bearings & Housing for above Rolls.

- M.S. fabricated heavy duty framing.

- Hydraulic loading mechanism on top roll .

- Doctors with Pneumatic Loading.

8 Scanner – JASH MAKING

9 POPE REEL:

Pope Reel Drum:

Dia. Of Pope Reel Drum: 900 mm

Face Length: 3950 mm

Material of Drum: Seamless Pipe

Bearing No. : 22324 k

Shell Thickness: 25 mm

Operating Speed: 400 meters/min.

Dynamic Blancing of Pope Reel Drum : 600 meters/min.

The Pope Reel drum is fabricated out of 22 mm thick M.S. Pipe and is machined and grounted on outer surface. The drum is mounted on two nos. antifirication roller bearing and is dynamically balanced to run at 400 meters/min. speed. The pope reeler drum is provided with water cooling arrangement.

Reel Change Mechanism:

The pope section is provided with the primary arm which is controlled by two nos. pneumatic cylinders of Bore 200 mm. The secondary arm is loaded with pneumatic cylinders of Bore 125 mm. The primary arm is also provided with reel spool locking arrangement of two nos. pneumatic cylinders of 75 mm bore.

Frame:

The frame of the Pope Reeler is fabricated out of M.S. Plate as heavy box section. The frame is machined accurately. The frames are coated with anti-rust pre-coating and painted with epoxy paint.

Camber Pipe:

Size: dia 135 mm x 4050 mm face.

Drum Doctor:

The drum doctor shall be fixed type. The fixed doctor body is made out of mild steel angle heavy duty type. Complete with ecentric cam, holding bracket etc to be fixed with the frame. The doctor holder is K-35 type and doctor blade is of fiber plate . The doctor holder lifting / lowering is done by as per our design .

Pneumatic Loading System and Control Desk:

The pope section is provided with pneumatic cylinder and pneumatic operating system and control desk operation.

Sole Plate :

The required set of sole plates is made out of cast iron construction of

rectangular solid type with grouting & Levelling Bolts.

Tambour Roll: 10 Nos Extra

Size: 323 mm dia x 3950 mm face length

Shell Thickness: 18 mm

Pipe O.D.: 323 mm

Bearing No.: 23120 cc & 23120 cck.

Material of Construction:The Tambour Roll shell is made out of Prime Quality seamless pipe having shell thickness 18 mm after machining with gudgeons of cast iron. The end journals of EN-8 and cast iron gudgeons are press fitted with the shell. The Tambour Roll is completely assembled, dynamically balanced and precisionally machined / ground for operating speed of 450 meters/min. The Tambour Rolls are equipped with FAG roller bearings inserted into C.I. bearing Housing.

10. Rewinder :

1] M.S Heavy duty , MS Framing Completed with Machining and Fabricated from 25mm , 16mm ,

12mm thick plates .

2] 2 Nos of unwinding one is having stands having the arrangement of break drum is having with Pneumatic Loading & Water Cooling Arrangement

3] 2 Nos Drum rolls having dia of 510 dia complete with machining and dynamically balanced

4] 2 Nos of rolls having one is Bow Roll and other one is chrom coated roll having dia of 270 mm fitted with 2 Nos Bearings

5] 1 No rider roll having dia of 250mm with Complete bottom Circular knifes .Load & unloaded with help of Penumatic Cylinder

6] 5 Nos Top Circular knives with pneumatic loading arrangement

7] Rewinder will be provided with shaft less arrangement

8] Reel ejector arrangement will be provided

9] Pneumatic cylinder for unloading cradle tray is provided to unloading of Rewinder roll

10] C.I Base Plate for Installation

Drives :

Two Nos Gear boxes are provided for drive the

both drum roll with help of 20 HP Motors of 1440 RPM

Control Panel

Panel is having the pneumatic control units for

all the operating of Pneumatic Controlls

A Breaking Drum Cylinder

B Pneumatic Loading & Unloading of rider roll

C Pneumatic Control Switch for ejector

D Pneumatic control switch for cradle

E Electric Machine Switch on-off

F Master Port for control speed of both motors with Variable Drives

G Individual port of Control of Main Motor Frequency Drive

H Emergency Stop Switch

11 . Paper Machine Mechanical Drive :

The Paper machine will be driven through sectional drive system . The mechanical drive equipments for the individual sections consist of the following :

Wire Part : Suction Couch Roll 1 Drive

FDR ROLL 1 Drive

Top Wire Part : Helping Drive Roll 1 Drive

Combination Roll 1 Drive

Middle Wire Part : Helping Drive Roll 1 Drive

Combination Roll 1 Drive

1st Press : ( Bottom Roll ) 1 Drive

2nd Press : (Top & Bottom Roll) 2 Drives

3rd Press : (Top & Bottom Roll) 2 Drives

Smoothing Press Section : 1 Drive

PRE Dryer Section : 12 Drives

Size Press : 2 Drives

Post Dryer Section : 8 Drives

Pope Reel : 1 Drives

Total: 35 Drives